Artec Industries

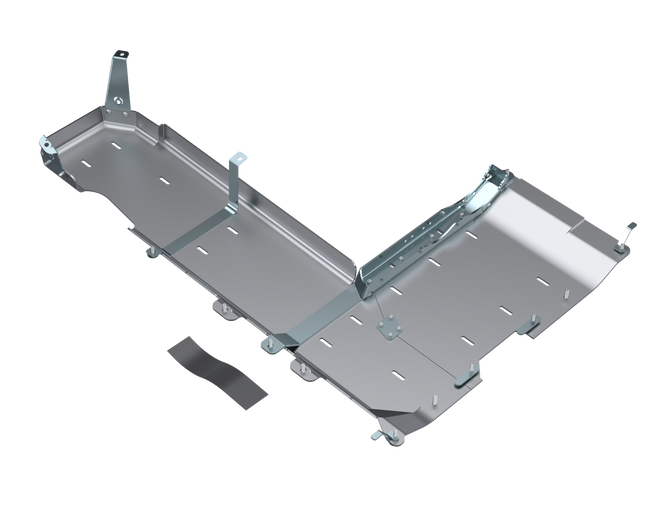

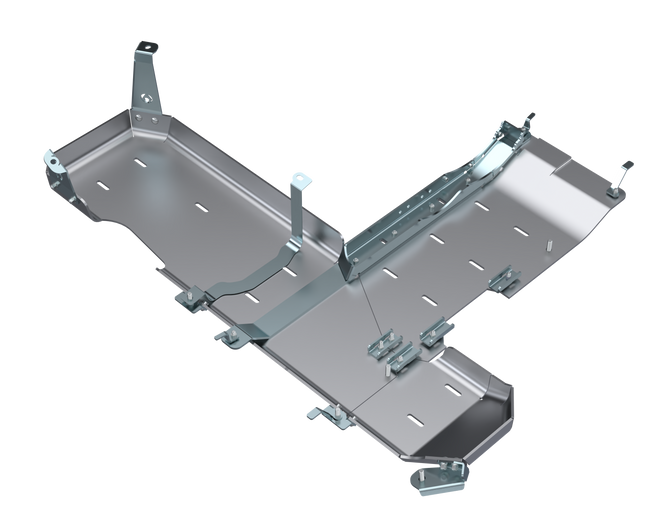

JL/JT Apex Front Axle Truss - A new era has begun with the arrival of the Apex truss! Artec Industries is proud to announce the next generation of patent pending axle trusses. This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the Apex truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous version with long weld seams which can be lead to extra weld warping of the axle, longer install times and can be inconsistent. This peaked structure not only applies to the axle tube between the coil perches but extends underneath the coil perches as well, forming a complete truss from end to end of axle, an industry first in an OEM axle application.

The JL Apex Front Axle Truss is based off of a JK Apex Truss that was secretly tested for over a year proving that even though the truss is lighter weight, the peaked structure of the truss holds up to both extreme applications and daily driving. The new JL Apex Front Axle Truss is the epitome of low cost, easy and quick to weld, simple, strong, and complete solutions for making your factory Jeep axle take more abuse than originally intended. You want easy insurance for your axle? The JL Apex Truss provides it.

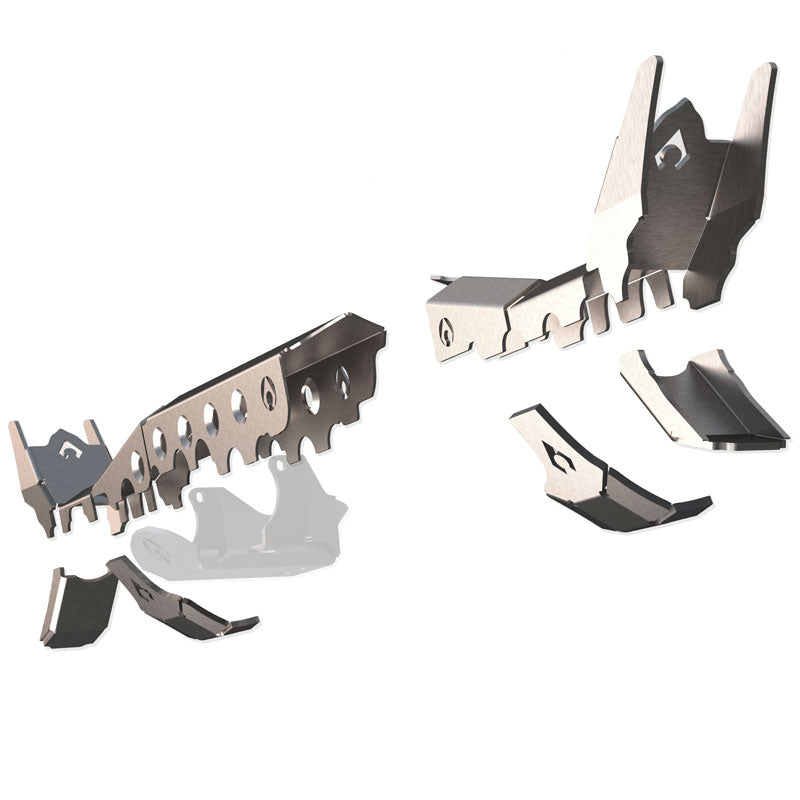

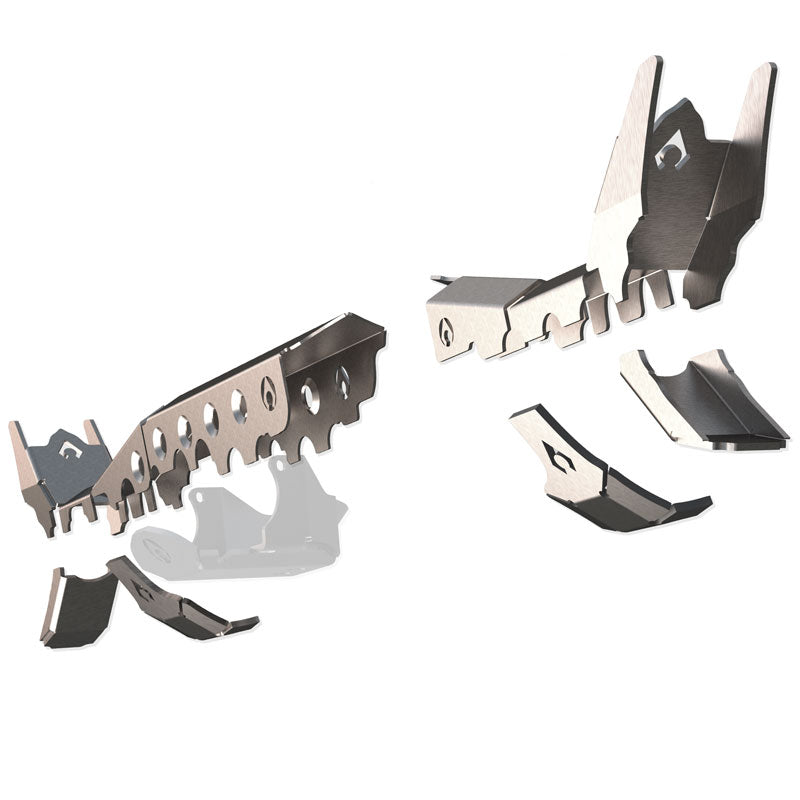

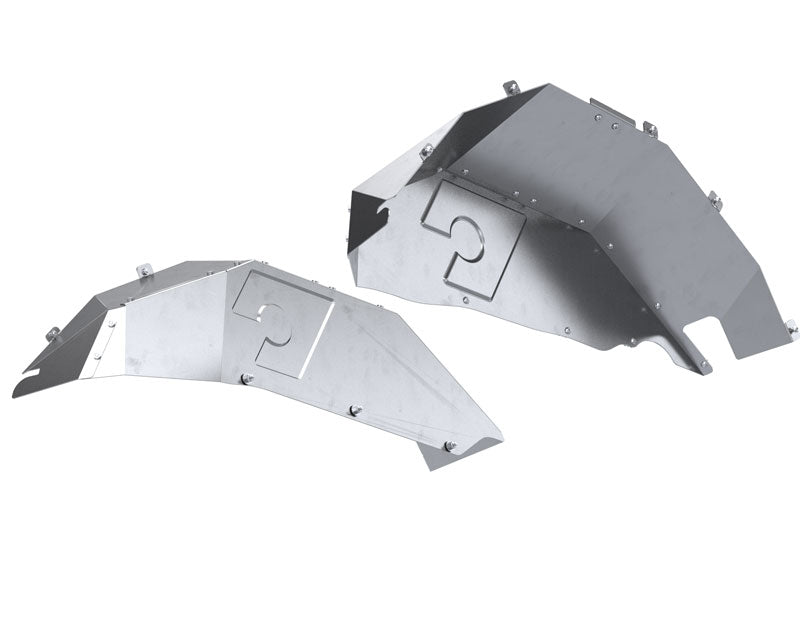

JL/JT Front LCA Skids - These heavy duty skids are designed to take serious abuse and reinforce your JL front axle lower control arm brackets. The 1/4 inch thick precision cut and formed components of this setup mean they'll install easily and protect your brackets and lower control arms.

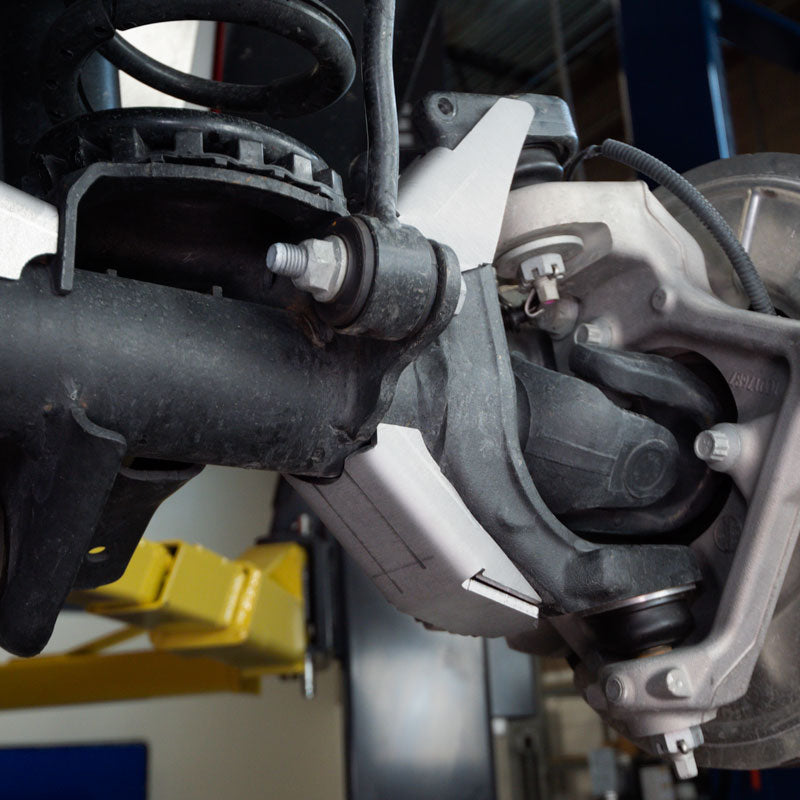

JL/JT Inner C Gussets - These heavy duty inner C gussets are designed to take serious abuse and reinforce your front Dana 30 or 44 JL or JT Inner C's. The 3/16 inch thick precision cut and formed components precisely contour and wrap around your inner c and add rigidity.

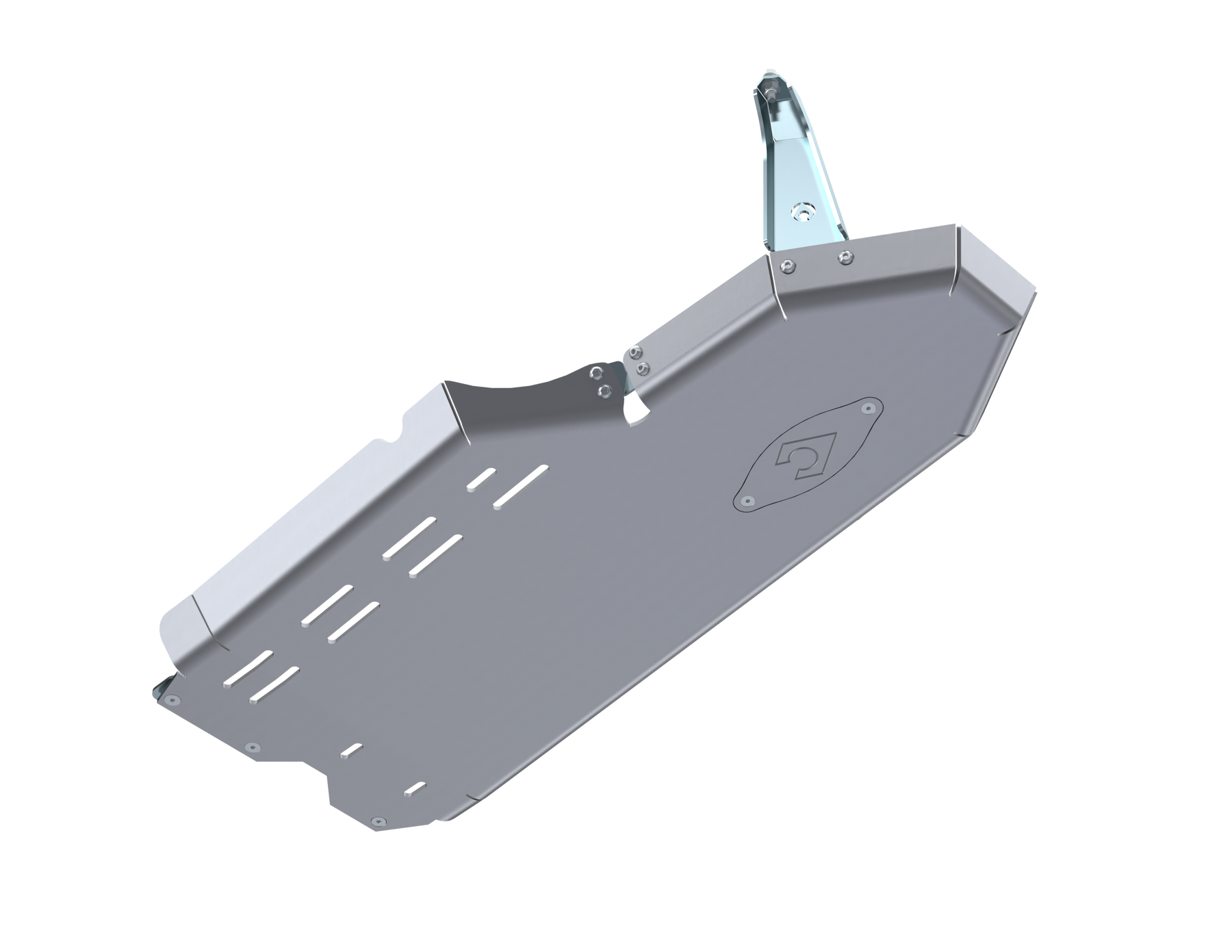

(Optional) JL shield - The new Jeep JL front axle now includes a new Center Axle Disconnect (CAD or Front Axle Disconnect FAD) system for improved fuel efficiency. This new inclusion on the axle features a very thin sheetmetal skid plate from the factory which is prone to bending and denting, not to mention being a rock magnet itself. Artec Industries is the first company to address this vulnerable part.

Our new JL shield is constructed from heavy duty 1/4 inch thick steel...twice the thickness of the OEM skid plate. The new design also uses countersunk flat head bolts for improved smoothness on the bottom...meaning you'll have less edges to catch on rocks. To improve the smoothness, we've eliminated unnecessary edges and extended the leading edge to the front of the axle and included an angled flange to protect the axle and allow rocks to glide under. The JL shield is fully welded and hard powdercoated for direct bolt-on installation and a long life.

Features:

- Patent pending Apex truss peaked top design provides more rigidity than a flat top truss design

- Truss is CNC Precision Laser cut in-house from 1/8 inch mild steel for a lightweight yet strong solution...only 6 lbs

- Truss is CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Dana Corp and Jeep for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Apex design continues under the OEM coil buckets for complete end-to-end axle reinforcement...an industry first

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours both the cast steel differential and FAD (front axle disconnect) and can be welded with normal MIG welder and moderate pre-heating and post-heating

- Provides worry-free wheeling of up to 40 inch tires on stock JL axles

- Bridges the Front Axle Disconnect (FAD/CAD) which has shown to be one of the weakest sections of the front axle

- Low Profile Design doesn't go over differential and allows usage in vehicles with only slight lift

- Front LCA Skids and Optional JL Shield made from 1/4 inch steel

- Inner C Gussets made from 3/16 inch steel

- Fits Jeep JL/JT Rubicon, JT MaxTow, All International JT

- Sold As: Kit

Product Videos

Vehicle Fitments

- Jeep Wrangler 2018 to 2025

- Jeep Gladiator 2020 to 2020

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

JL/JT Apex Front Axle Truss - A new era has begun with the arrival of the Apex truss! Artec Industries is proud to announce the next generation of patent pending axle trusses. This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the Apex truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous version with long weld seams which can be lead to extra weld warping of the axle, longer install times and can be inconsistent. This peaked structure not only applies to the axle tube between the coil perches but extends underneath the coil perches as well, forming a complete truss from end to end of axle, an industry first in an OEM axle application.

The JL Apex Front Axle Truss is based off of a JK Apex Truss that was secretly tested for over a year proving that even though the truss is lighter weight, the peaked structure of the truss holds up to both extreme applications and daily driving. The new JL Apex Front Axle Truss is the epitome of low cost, easy and quick to weld, simple, strong, and complete solutions for making your factory Jeep axle take more abuse than originally intended. You want easy insurance for your axle? The JL Apex Truss provides it.

JL/JT Front LCA Skids - These heavy duty skids are designed to take serious abuse and reinforce your JL front axle lower control arm brackets. The 1/4 inch thick precision cut and formed components of this setup mean they'll install easily and protect your brackets and lower control arms.

JL/JT Inner C Gussets - These heavy duty inner C gussets are designed to take serious abuse and reinforce your front Dana 30 or 44 JL or JT Inner C's. The 3/16 inch thick precision cut and formed components precisely contour and wrap around your inner c and add rigidity.

(Optional) JL shield - The new Jeep JL front axle now includes a new Center Axle Disconnect (CAD or Front Axle Disconnect FAD) system for improved fuel efficiency. This new inclusion on the axle features a very thin sheetmetal skid plate from the factory which is prone to bending and denting, not to mention being a rock magnet itself. Artec Industries is the first company to address this vulnerable part.

Our new JL shield is constructed from heavy duty 1/4 inch thick steel...twice the thickness of the OEM skid plate. The new design also uses countersunk flat head bolts for improved smoothness on the bottom...meaning you'll have less edges to catch on rocks. To improve the smoothness, we've eliminated unnecessary edges and extended the leading edge to the front of the axle and included an angled flange to protect the axle and allow rocks to glide under. The JL shield is fully welded and hard powdercoated for direct bolt-on installation and a long life.

Features:

- Patent pending Apex truss peaked top design provides more rigidity than a flat top truss design

- Truss is CNC Precision Laser cut in-house from 1/8 inch mild steel for a lightweight yet strong solution...only 6 lbs

- Truss is CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Dana Corp and Jeep for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Apex design continues under the OEM coil buckets for complete end-to-end axle reinforcement...an industry first

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours both the cast steel differential and FAD (front axle disconnect) and can be welded with normal MIG welder and moderate pre-heating and post-heating

- Provides worry-free wheeling of up to 40 inch tires on stock JL axles

- Bridges the Front Axle Disconnect (FAD/CAD) which has shown to be one of the weakest sections of the front axle

- Low Profile Design doesn't go over differential and allows usage in vehicles with only slight lift

- Front LCA Skids and Optional JL Shield made from 1/4 inch steel

- Inner C Gussets made from 3/16 inch steel

- Fits Jeep JT Sport, JT Overland, JL International (Non-US/Canada) Rubicon

- Sold As: Kit

Product Videos

Vehicle Fitments

- Jeep Wrangler 2018 to 2025

- Jeep Gladiator 2020 to 2020

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

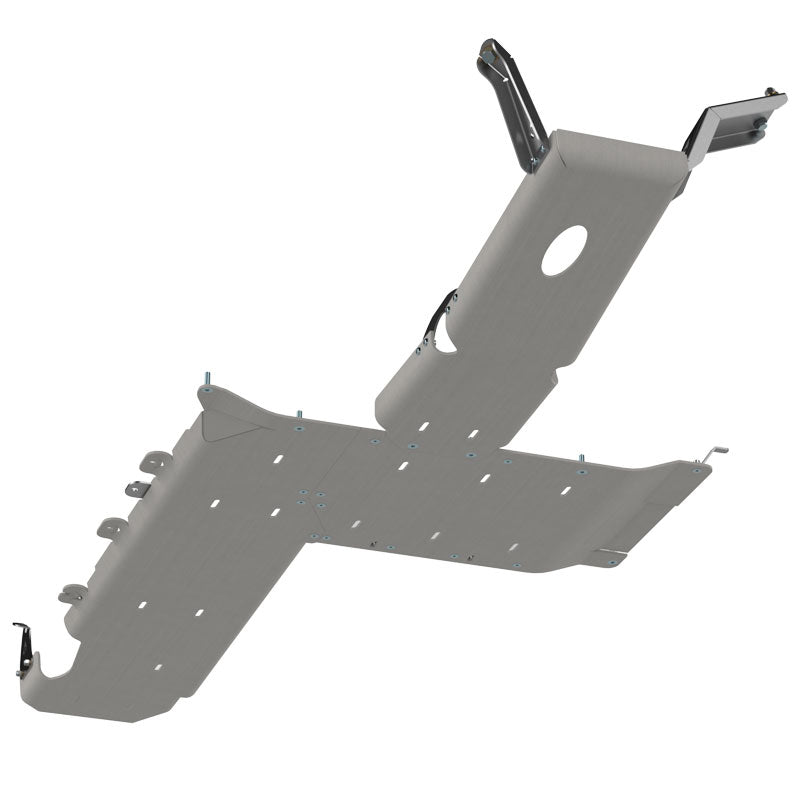

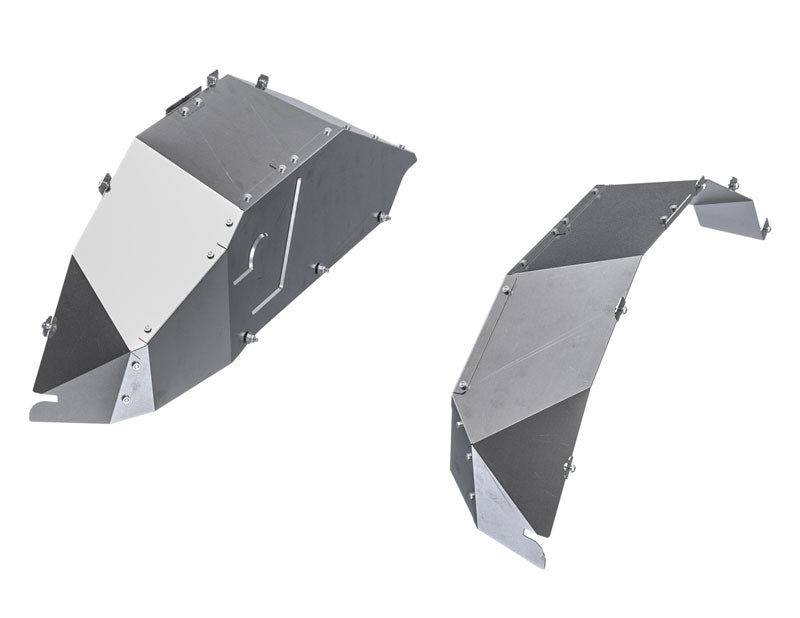

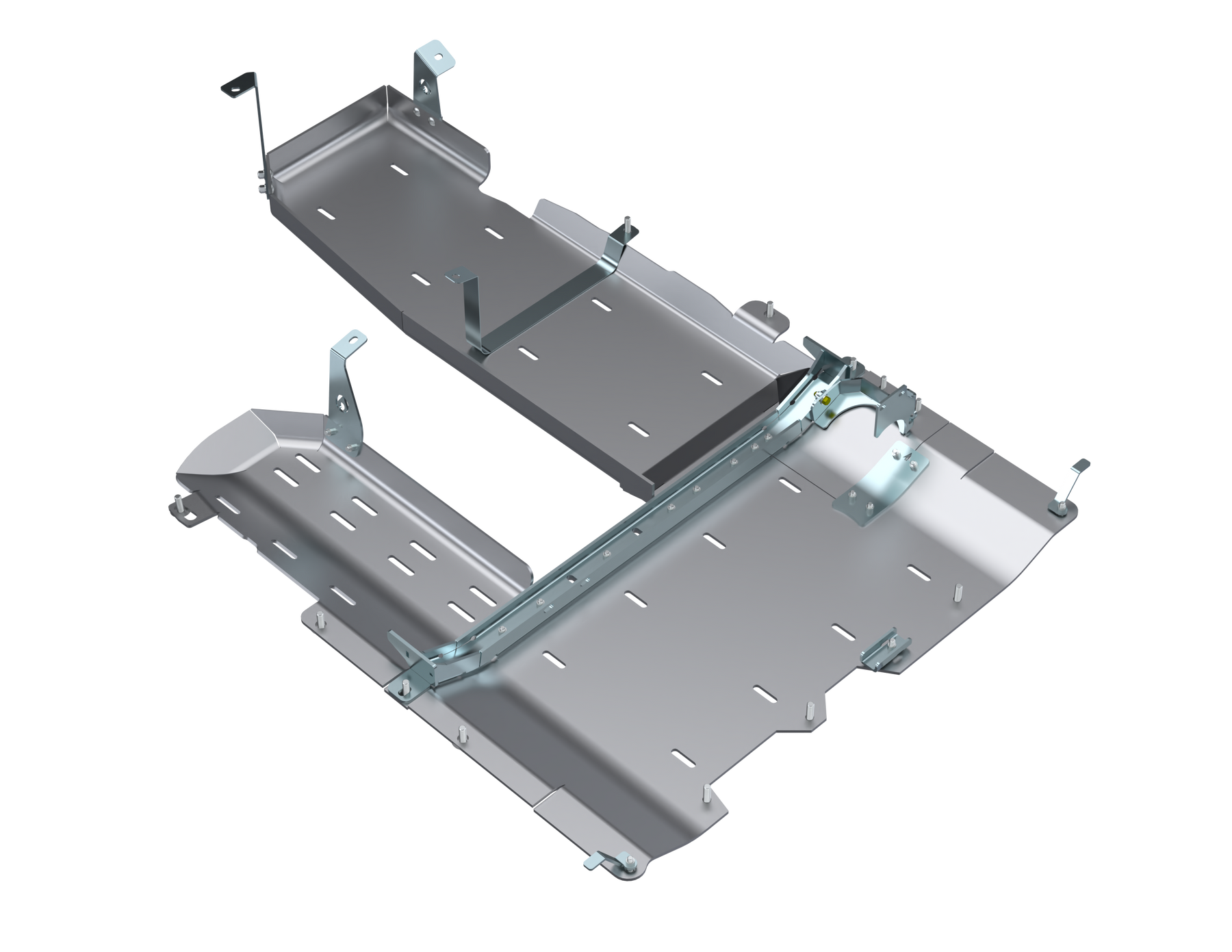

A new era has begun with the arrival of the APEX Truss! Artec Industries is proud to announce the next generation of Patent Pending axle trusses. This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the APEX truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous version with long weld seams which can be lead to extra weld warping of the axle, longer install times and can be inconsistent. Without long seams to weld, now you drop the truss directly on to the axle and weld it to the axle faster.

We started the Jeep 1 ton Revolution and now we're taking it to the next level. The new APEX swap kit is designed to have a simpler, faster install, with less parts and weight and lower price. We've worked hard to improve everything, from making the truss easier to weld, to less warping from welding, to optimizing the shock bracket locations and lowering the upper control arm mounts for more clearance and better geometry.

The improvements made have been suggested by our network of dealer/installers who build these kits every day. Now they are a reality. The new 1 Ton APEX Front Swap Kit delivers in every way.

This heavy duty truss and bracket system is designed to take serious abuse and reinforce your entire axle while also providing the factory link, spring, anti-sway bar, and shock locations. The 3/16 inch thick truss incorporates a unique peaked design to strengthen both the axle and incorporate the link brackets for ease of installation and added strength.

By using the truss to align the link mounts, hours of work and trial and error can be avoided when compared to other bracket systems. Simply tack weld the truss on the axle, and all the other brackets fit into place exactly where they need to be.

Features include:

- JL 1 Ton APEX Front Kingpin/Balljoint 60 Swap 1985-1997

- With Daystar Bushings

- Patent Pending APEX Truss peaked top design provides more rigidity than a flat top truss design

- CNC Precision Laser cut in-house from 1/4 inch and 3/16 inch mild steel for a lightweight yet strong solution...starting at only 30 lbs total

- CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Ford, Jeep and In-house 3D scanning for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours both the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- OEM location Upper Control Arms mount to an ultra high clearance Differential Bridge that hugs the shape of the casting (bushing or Johnny Joint option)

- Truss extends under coil buckets all the way to inner C for end-to-end rigidity

- Multi-piece truss design means smaller packaging and less shipping costs along with easy installation

- Using a 1 ton axle will support larger tires and less chance of breakage in extreme conditions

- Coil brackets and bump stop pads are combined to form an axle tube truss and allows for easy installment of other brackets

- Includes all the brackets necessary for a complete axle swap including upper and lower control arm mounts, shock mounts, anti-sway bar mounts, trackbar mount, bumpstop pads and coil spring mounts.

- Heavy duty Trackbar bracket can slide to multiple positions for steering geometry fine tuning

- Shock brackets have been moved up and out (compared JK OEM position) for a slightly higher clearance for lower control arms and frame

- Overall low profile design means your axle is stronger, sleeker, easier to fit into any vehicle, and less likely to interfere with vehicle components

Important Notes:

- The Front 60 that works with this kit is from Ford F-250 and F-350 trucks from model years 1985-1991.5 (kingpin) and 1992-1997 (balljoint). This truss is not intended for newer axles due to different differential offsets, axle tube sizes and differential contours.

- Trimming of the factory differential casting may be necessary (see instructions). Other fabrication and modifications may be needed due to variances in lift kits and other factors. Removal of passenger side leaf spring perch is necessary.

- Due to the larger casting on the 60 differential, the Lower Control Arm (LCA) brackets are wider than factory location (41.5 inch Center to Center). Modifications to your Lower Control Arms will likely be necessary. If you have adjustable arms with flexible style joints (heims, Johnny Joints, etc), modifications may not be necessary. Upper Control Arm (UCA) brackets are also slightly higher than factory so adjustable arms may be necessary. The shock mounts are also slightly higher (1.25 inch) than stock to clear the lower control arms.

- This kit does not include any parts for ABS sensors. It is only a bracket kit. Hooking up and configuring these sensors is the responsibility of the end user.

- 60 axles Do Not Match the factory JK 5 lug wheel bolt pattern. New wheels will need to be purchased to do this swap. Brake and Steering components Not Included in this product, but will be available soon.

- This will likely require bumpstop extensions and a new trackbar since the steering is different on this axle from factory axle. The trackbar bracket is higher than stock location to allow proper steering geometry.

- Minor modifications to the ends of the truss that contact the inner C may be necssary for balljoint axles 1992-97.

Product Videos

Vehicle Fitments

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

A new era has begun with the arrival of the APEX Truss! Artec Industries is proud to announce the next generation of Patent Pending axle trusses. This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the APEX truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous version with long weld seams which can be lead to extra weld warping of the axle, longer install times and can be inconsistent. Without long seams to weld, now you drop the truss directly on to the axle and weld it to the axle faster.

We started the Jeep 1 ton Revolution and now we're taking it to the next level. The new APEX swap kit is designed to have a simpler, faster install, with less parts and weight and lower price. We've worked hard to improve everything, from making the truss easier to weld, to less warping from welding, to optimizing the shock bracket locations and lowering the upper control arm mounts for more clearance and better geometry.

The improvements made have been suggested by our network of dealer/installers who build these kits every day. Now they are a reality. The new 1 Ton APEX Front Swap Kit delivers in every way.

This heavy duty truss and bracket system is designed to take serious abuse and reinforce your entire axle while also providing the factory link, spring, anti-sway bar, and shock locations. The 3/16 inch thick truss incorporates a unique peaked design to strengthen both the axle and incorporate the link brackets for ease of installation and added strength.

By using the truss to align the link mounts, hours of work and trial and error can be avoided when compared to other bracket systems. Simply tack weld the truss on the axle, and all the other brackets fit into place exactly where they need to be.

Features include:

- JL 1 Ton APEX Front Kingpin/Balljoint 60 Swap 1985-1997

- With Currie Johnny Joints

- Patent Pending APEX Truss peaked top design provides more rigidity than a flat top truss design

- CNC Precision Laser cut in-house from 1/4 inch and 3/16 inch mild steel for a lightweight yet strong solution...starting at only 30 lbs total

- CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Ford, Jeep and In-house 3D scanning for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours both the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- OEM location Upper Control Arms mount to an ultra high clearance Differential Bridge that hugs the shape of the casting (bushing or Johnny Joint option)

- Truss extends under coil buckets all the way to inner C for end-to-end rigidity

- Multi-piece truss design means smaller packaging and less shipping costs along with easy installation

- Using a 1 ton axle will support larger tires and less chance of breakage in extreme conditions

- Coil brackets and bump stop pads are combined to form an axle tube truss and allows for easy installment of other brackets

- Includes all the brackets necessary for a complete axle swap including upper and lower control arm mounts, shock mounts, anti-sway bar mounts, trackbar mount, bumpstop pads and coil spring mounts.

- Heavy duty Trackbar bracket can slide to multiple positions for steering geometry fine tuning

- Shock brackets have been moved up and out (compared JK OEM position) for a slightly higher clearance for lower control arms and frame

- Overall low profile design means your axle is stronger, sleeker, easier to fit into any vehicle, and less likely to interfere with vehicle components

Important Notes:

- The Front 60 that works with this kit is from Ford F-250 and F-350 trucks from model years 1985-1991.5 (kingpin) and 1992-1997 (balljoint). This truss is not intended for newer axles due to different differential offsets, axle tube sizes and differential contours.

- Trimming of the factory differential casting may be necessary (see instructions). Other fabrication and modifications may be needed due to variances in lift kits and other factors. Removal of passenger side leaf spring perch is necessary.

- Due to the larger casting on the 60 differential, the Lower Control Arm (LCA) brackets are wider than factory location (41.5 inch Center to Center). Modifications to your Lower Control Arms will likely be necessary. If you have adjustable arms with flexible style joints (heims, Johnny Joints, etc), modifications may not be necessary. Upper Control Arm (UCA) brackets are also slightly higher than factory so adjustable arms may be necessary. The shock mounts are also slightly higher (1.25 inch) than stock to clear the lower control arms.

- This kit does not include any parts for ABS sensors. It is only a bracket kit. Hooking up and configuring these sensors is the responsibility of the end user.

- 60 axles Do Not Match the factory JK 5 lug wheel bolt pattern. New wheels will need to be purchased to do this swap. Brake and Steering components Not Included in this product, but will be available soon.

- This will likely require bumpstop extensions and a new trackbar since the steering is different on this axle from factory axle. The trackbar bracket is higher than stock location to allow proper steering geometry.

- Minor modifications to the ends of the truss that contact the inner C may be necssary for balljoint axles 1992-97.

Product Videos

Vehicle Fitments

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

A new era has begun with the arrival of the APEX Truss! Artec Industries is proud to announce the next generation of Patent Pending axle trusses. This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the APEX truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous version with long weld seams which can be lead to extra weld warping of the axle, longer install times and can be inconsistent. Without long seams to weld, now you drop the truss directly on to the axle and weld it to the axle faster.

We started the Jeep 1 ton Revolution and now we're taking it to the next level. The new APEX swap kit is designed to have a simpler, faster install, with less parts and weight and lower price. We've worked hard to improve everything, from making the truss easier to weld, to less warping from welding, to optimizing the shock bracket locations and lowering the upper control arm mounts for more clearance and better geometry.

The improvements made have been suggested by our network of dealer/installers who build these kits every day. Now they are a reality. The new 1 Ton APEX Front Swap Kit delivers in every way.

This heavy duty truss and bracket system is designed to take serious abuse and reinforce your entire axle while also providing the factory link, spring, anti-sway bar, and shock locations. The 3/16 inch thick truss incorporates a unique peaked design to strengthen both the axle and incorporate the link brackets for ease of installation and added strength.

By using the truss to align the link mounts, hours of work and trial and error can be avoided when compared to other bracket systems. Simply tack weld the truss on the axle, and all the other brackets fit into place exactly where they need to be.

Features include:

- JL 1 Ton APEX Front Kingpin/Balljoint 60 Swap 1985-1997

- With Adjustable Truss Upper Link Mount

- Patent Pending APEX Truss peaked top design provides more rigidity than a flat top truss design

- CNC Precision Laser cut in-house from 1/4 inch and 3/16 inch mild steel for a lightweight yet strong solution...starting at only 30 lbs total

- CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Ford, Jeep and In-house 3D scanning for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours both the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- OEM location Upper Control Arms mount to an ultra high clearance Differential Bridge that hugs the shape of the casting (bushing or Johnny Joint option)

- Truss extends under coil buckets all the way to inner C for end-to-end rigidity

- Multi-piece truss design means smaller packaging and less shipping costs along with easy installation

- Using a 1 ton axle will support larger tires and less chance of breakage in extreme conditions

- Coil brackets and bump stop pads are combined to form an axle tube truss and allows for easy installment of other brackets

- Includes all the brackets necessary for a complete axle swap including upper and lower control arm mounts, shock mounts, anti-sway bar mounts, trackbar mount, bumpstop pads and coil spring mounts.

- Heavy duty Trackbar bracket can slide to multiple positions for steering geometry fine tuning

- Shock brackets have been moved up and out (compared JK OEM position) for a slightly higher clearance for lower control arms and frame

- Overall low profile design means your axle is stronger, sleeker, easier to fit into any vehicle, and less likely to interfere with vehicle components

Important Notes:

- The Front 60 that works with this kit is from Ford F-250 and F-350 trucks from model years 1985-1991.5 (kingpin) and 1992-1997 (balljoint). This truss is not intended for newer axles due to different differential offsets, axle tube sizes and differential contours.

- Trimming of the factory differential casting may be necessary (see instructions). Other fabrication and modifications may be needed due to variances in lift kits and other factors. Removal of passenger side leaf spring perch is necessary.

- Due to the larger casting on the 60 differential, the Lower Control Arm (LCA) brackets are wider than factory location (41.5 inch Center to Center). Modifications to your Lower Control Arms will likely be necessary. If you have adjustable arms with flexible style joints (heims, Johnny Joints, etc), modifications may not be necessary. Upper Control Arm (UCA) brackets are also slightly higher than factory so adjustable arms may be necessary. The shock mounts are also slightly higher (1.25 inch) than stock to clear the lower control arms.

- This kit does not include any parts for ABS sensors. It is only a bracket kit. Hooking up and configuring these sensors is the responsibility of the end user.

- 60 axles Do Not Match the factory JK 5 lug wheel bolt pattern. New wheels will need to be purchased to do this swap. Brake and Steering components Not Included in this product, but will be available soon.

- This will likely require bumpstop extensions and a new trackbar since the steering is different on this axle from factory axle. The trackbar bracket is higher than stock location to allow proper steering geometry.

- Minor modifications to the ends of the truss that contact the inner C may be necssary for balljoint axles 1992-97.

Product Videos

Vehicle Fitments

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

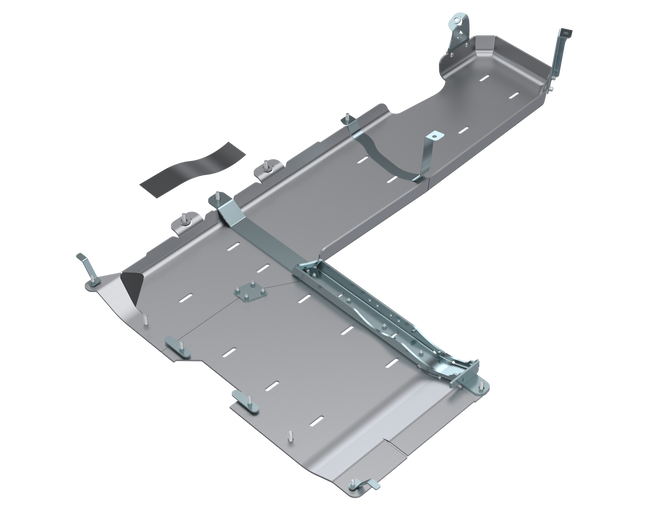

A new era has begun with the arrival of the APEX Truss! Artec Industries is proud to announce the next generation of Patent Pending axle trusses. This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the APEX truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous version with long weld seams which can be lead to extra weld warping of the axle, longer install times and can be inconsistent. Without long seams to weld, now you drop the truss directly on to the axle and weld it to the axle faster.

We started the Jeep 1 ton Revolution and now we're taking it to the next level. The new APEX swap kit is designed to have a simpler, faster install, with less parts and weight and lower price. We've worked hard to improve everything, from making the truss easier to weld, to less warping from welding, to optimizing the shock bracket locations and lowering the upper control arm mounts for more clearance and better geometry.

The improvements made have been suggested by our network of dealer/installers who build these kits every day. Now they are a reality. The new 1 Ton APEX Front Swap Kit delivers in every way.

This heavy duty truss and bracket system is designed to take serious abuse and reinforce your entire axle while also providing the factory link, spring, anti-sway bar, and shock locations. The 3/16 inch thick truss incorporates a unique peaked design to strengthen both the axle and incorporate the link brackets for ease of installation and added strength.

By using the truss to align the link mounts, hours of work and trial and error can be avoided when compared to other bracket systems. Simply tack weld the truss on the axle, and all the other brackets fit into place exactly where they need to be.

Features include:

- JL 1 Ton APEX Front Superduty Swap Kit 1999-2004

- With Adjustable Truss Upper Link Mount

- Patent Pending APEX Truss peaked top design provides more rigidity than a flat top truss design

- CNC Precision Laser cut in-house from 1/4 inch and 3/16 inch mild steel for a lightweight yet strong solution...starting at only 30 lbs total

- CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Ford, Jeep and In-house 3D scanning for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours both the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- OEM location Upper Control Arms mount to an ultra high clearance Differential Bridge that hugs the shape of the casting (bushing or Johnny Joint option)

- Truss extends under coil buckets all the way to inner C for end-to-end rigidity

- Multi-piece truss design means smaller packaging and less shipping costs along with easy installation

- Using a 1 ton axle will support larger tires and less chance of breakage in extreme conditions

- Coil brackets and bump stop pads are combined to form an axle tube truss and allows for easy installment of other brackets

- Includes all the brackets necessary for a complete axle swap including upper and lower control arm mounts, shock mounts, anti-sway bar mounts, trackbar mount, bumpstop pads and coil spring mounts.

- Heavy duty Trackbar bracket can slide to multiple positions for steering geometry fine tuning

- Shock brackets have been moved up and out (compared JK OEM position) for a slightly higher clearance for lower control arms and frame

- Overall low profile design means your axle is stronger, sleeker, easier to fit into any vehicle, and less likely to interfere with vehicle components

Important Notes:

- The Front 60 that works with this kit is from Ford F-250 and F-350 trucks from model years 1999-2004 (leaf spring). This truss is not intended for newer axles due to different differential offsets.

- Trimming of the factory differential casting may be necessary (see instructions). Other fabrication and modifications may be needed due to variances in lift kits and other factors. Removal of passenger side leaf spring perch is necessary.

- Due to the larger casting on the 60 differential, the Lower Control Arm (LCA) brackets are wider than factory location (41.5 inch Center to Center). Modifications to your Lower Control Arms will likely be necessary. If you have adjustable arms with flexible style joints (heims, Johnny Joints, etc), modifications may not be necessary. Upper Control Arm (UCA) brackets are also slightly higher than factory so adjustable arms may be necessary. The shock mounts are also slightly higher (1.25 inch) than stock to clear the lower control arms.

- This kit does not include any parts for ABS sensors. It is only a bracket kit. Hooking up and configuring these sensors is the responsibility of the end user.

- 60 axles Do Not Match the factory JK 5 lug wheel bolt pattern. New wheels will need to be purchased to do this swap. Brake and Steering components Not Included in this product, but will be available soon.

- This will likely require bumpstop extensions and a new trackbar since the steering is different on this axle from factory axle. The trackbar bracket is higher than stock location to allow proper steering geometry.

Product Videos

Vehicle Fitments

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

A new era has begun with the arrival of the APEX Truss! Artec Industries is proud to announce the next generation of Patent Pending axle trusses. This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the APEX truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous version with long weld seams which can be lead to extra weld warping of the axle, longer install times and can be inconsistent. Without long seams to weld, now you drop the truss directly on to the axle and weld it to the axle faster.

We started the Jeep 1 ton Revolution and now we're taking it to the next level. The new APEX swap kit is designed to have a simpler, faster install, with less parts and weight and lower price. We've worked hard to improve everything, from making the truss easier to weld, to less warping from welding, to optimizing the shock bracket locations and lowering the upper control arm mounts for more clearance and better geometry.

The improvements made have been suggested by our network of dealer/installers who build these kits every day. Now they are a reality. The new 1 Ton APEX Front Swap Kit delivers in every way.

This heavy duty truss and bracket system is designed to take serious abuse and reinforce your entire axle while also providing the factory link, spring, anti-sway bar, and shock locations. The 3/16 inch thick truss incorporates a unique peaked design to strengthen both the axle and incorporate the link brackets for ease of installation and added strength.

By using the truss to align the link mounts, hours of work and trial and error can be avoided when compared to other bracket systems. Simply tack weld the truss on the axle, and all the other brackets fit into place exactly where they need to be.

Features include:

- JL 1 Ton APEX Front Superduty Swap Kit 2005-Present

- With Daystar Bushings

- Patent Pending APEX Truss peaked top design provides more rigidity than a flat top truss design

- CNC Precision Laser cut in-house from 1/4 inch and 3/16 inch mild steel for a lightweight yet strong solution...starting at only 30 lbs total

- CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Ford, Jeep and In-house 3D scanning for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours both the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- OEM location Upper Control Arms mount to an ultra high clearance Differential Bridge that hugs the shape of the casting (bushing or Johnny Joint option)

- Truss extends under coil buckets all the way to inner C for end-to-end rigidity

- Multi-piece truss design means smaller packaging and less shipping costs along with easy installation

- Using a 1 ton axle will support larger tires and less chance of breakage in extreme conditions

- Coil brackets and bump stop pads are combined to form an axle tube truss and allows for easy installment of other brackets

- Includes all the brackets necessary for a complete axle swap including upper and lower control arm mounts, shock mounts, anti-sway bar mounts, trackbar mount, bumpstop pads and coil spring mounts.

- Heavy duty Trackbar bracket can slide to multiple positions for steering geometry fine tuning

- Shock brackets have been moved up and out (compared JK OEM position) for a slightly higher clearance for lower control arms and frame

- Overall low profile design means your axle is stronger, sleeker, easier to fit into any vehicle, and less likely to interfere with vehicle components

Important Notes:

- The Front 60 that works with this kit is from Ford F-250 and F-350 trucks from model years 2005 and up (coil spring). This truss is not intended for newer axles due to different differential offsets.

- Trimming of the factory differential casting may be necessary (see instructions). Other fabrication and modifications may be needed due to variances in lift kits and other factors. Removal of passenger side leaf spring perch is necessary.

- Due to the larger casting on the 60 differential, the Lower Control Arm (LCA) brackets are wider than factory location (41.5 inch Center to Center). Modifications to your Lower Control Arms will likely be necessary. If you have adjustable arms with flexible style joints (heims, Johnny Joints, etc), modifications may not be necessary. Upper Control Arm (UCA) brackets are also slightly higher than factory so adjustable arms may be necessary. The shock mounts are also slightly higher (1.25 inch) than stock to clear the lower control arms.

- This kit does not include any parts for ABS sensors. It is only a bracket kit. Hooking up and configuring these sensors is the responsibility of the end user.

- 60 axles Do Not Match the factory JK 5 lug wheel bolt pattern. New wheels will need to be purchased to do this swap. Brake and Steering components Not Included in this product, but will be available soon.

- This will likely require bumpstop extensions and a new trackbar since the steering is different on this axle from factory axle. The trackbar bracket is higher than stock location to allow proper steering geometry.

Product Videos

Vehicle Fitments

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

A new era has begun with the arrival of the APEX Truss! Artec Industries is proud to announce the next generation of Patent Pending axle trusses. This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the APEX truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous version with long weld seams which can be lead to extra weld warping of the axle, longer install times and can be inconsistent. Without long seams to weld, now you drop the truss directly on to the axle and weld it to the axle faster.

We started the Jeep 1 ton Revolution and now we're taking it to the next level. The new APEX swap kit is designed to have a simpler, faster install, with less parts and weight and lower price. We've worked hard to improve everything, from making the truss easier to weld, to less warping from welding, to optimizing the shock bracket locations and lowering the upper control arm mounts for more clearance and better geometry.

The improvements made have been suggested by our network of dealer/installers who build these kits every day. Now they are a reality. The new 1 Ton APEX Front Swap Kit delivers in every way.

This heavy duty truss and bracket system is designed to take serious abuse and reinforce your entire axle while also providing the factory link, spring, anti-sway bar, and shock locations. The 3/16 inch thick truss incorporates a unique peaked design to strengthen both the axle and incorporate the link brackets for ease of installation and added strength.

By using the truss to align the link mounts, hours of work and trial and error can be avoided when compared to other bracket systems. Simply tack weld the truss on the axle, and all the other brackets fit into place exactly where they need to be.

Features include:

- JL 1 Ton APEX Front Superduty Swap Kit 2005-Present

- With Currie Johnny Joints

- Patent Pending APEX Truss peaked top design provides more rigidity than a flat top truss design

- CNC Precision Laser cut in-house from 1/4 inch and 3/16 inch mild steel for a lightweight yet strong solution...starting at only 30 lbs total

- CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Ford, Jeep and In-house 3D scanning for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours both the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- OEM location Upper Control Arms mount to an ultra high clearance Differential Bridge that hugs the shape of the casting (bushing or Johnny Joint option)

- Truss extends under coil buckets all the way to inner C for end-to-end rigidity

- Multi-piece truss design means smaller packaging and less shipping costs along with easy installation

- Using a 1 ton axle will support larger tires and less chance of breakage in extreme conditions

- Coil brackets and bump stop pads are combined to form an axle tube truss and allows for easy installment of other brackets

- Includes all the brackets necessary for a complete axle swap including upper and lower control arm mounts, shock mounts, anti-sway bar mounts, trackbar mount, bumpstop pads and coil spring mounts.

- Heavy duty Trackbar bracket can slide to multiple positions for steering geometry fine tuning

- Shock brackets have been moved up and out (compared JK OEM position) for a slightly higher clearance for lower control arms and frame

- Overall low profile design means your axle is stronger, sleeker, easier to fit into any vehicle, and less likely to interfere with vehicle components

Important Notes:

- The Front 60 that works with this kit is from Ford F-250 and F-350 trucks from model years 2005 and up (coil spring). This truss is not intended for newer axles due to different differential offsets.

- Trimming of the factory differential casting may be necessary (see instructions). Other fabrication and modifications may be needed due to variances in lift kits and other factors. Removal of passenger side leaf spring perch is necessary.

- Due to the larger casting on the 60 differential, the Lower Control Arm (LCA) brackets are wider than factory location (41.5 inch Center to Center). Modifications to your Lower Control Arms will likely be necessary. If you have adjustable arms with flexible style joints (heims, Johnny Joints, etc), modifications may not be necessary. Upper Control Arm (UCA) brackets are also slightly higher than factory so adjustable arms may be necessary. The shock mounts are also slightly higher (1.25 inch) than stock to clear the lower control arms.

- This kit does not include any parts for ABS sensors. It is only a bracket kit. Hooking up and configuring these sensors is the responsibility of the end user.

- 60 axles Do Not Match the factory JK 5 lug wheel bolt pattern. New wheels will need to be purchased to do this swap. Brake and Steering components Not Included in this product, but will be available soon.

- This will likely require bumpstop extensions and a new trackbar since the steering is different on this axle from factory axle. The trackbar bracket is higher than stock location to allow proper steering geometry.

Product Videos

Vehicle Fitments

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

A new era has begun with the arrival of the APEX Truss! Artec Industries is proud to announce the next generation of Patent Pending axle trusses. This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the APEX truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous version with long weld seams which can be lead to extra weld warping of the axle, longer install times and can be inconsistent. Without long seams to weld, now you drop the truss directly on to the axle and weld it to the axle faster.

We started the Jeep 1 ton Revolution and now we're taking it to the next level. The new APEX swap kit is designed to have a simpler, faster install, with less parts and weight and lower price. We've worked hard to improve everything, from making the truss easier to weld, to less warping from welding, to optimizing the shock bracket locations and lowering the upper control arm mounts for more clearance and better geometry.

The improvements made have been suggested by our network of dealer/installers who build these kits every day. Now they are a reality. The new 1 Ton APEX Front Swap Kit delivers in every way.

This heavy duty truss and bracket system is designed to take serious abuse and reinforce your entire axle while also providing the factory link, spring, anti-sway bar, and shock locations. The 3/16 inch thick truss incorporates a unique peaked design to strengthen both the axle and incorporate the link brackets for ease of installation and added strength.

By using the truss to align the link mounts, hours of work and trial and error can be avoided when compared to other bracket systems. Simply tack weld the truss on the axle, and all the other brackets fit into place exactly where they need to be.

Features include:

- JL 1 Ton APEX Front Superduty Swap Kit 2005-Present

- With Adjustable Truss Upper Link Mount

- Patent Pending APEX Truss peaked top design provides more rigidity than a flat top truss design

- CNC Precision Laser cut in-house from 1/4 inch and 3/16 inch mild steel for a lightweight yet strong solution...starting at only 30 lbs total

- CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Ford, Jeep and In-house 3D scanning for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours both the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- OEM location Upper Control Arms mount to an ultra high clearance Differential Bridge that hugs the shape of the casting (bushing or Johnny Joint option)

- Truss extends under coil buckets all the way to inner C for end-to-end rigidity

- Multi-piece truss design means smaller packaging and less shipping costs along with easy installation

- Using a 1 ton axle will support larger tires and less chance of breakage in extreme conditions

- Coil brackets and bump stop pads are combined to form an axle tube truss and allows for easy installment of other brackets

- Includes all the brackets necessary for a complete axle swap including upper and lower control arm mounts, shock mounts, anti-sway bar mounts, trackbar mount, bumpstop pads and coil spring mounts.

- Heavy duty Trackbar bracket can slide to multiple positions for steering geometry fine tuning

- Shock brackets have been moved up and out (compared JK OEM position) for a slightly higher clearance for lower control arms and frame

- Overall low profile design means your axle is stronger, sleeker, easier to fit into any vehicle, and less likely to interfere with vehicle components

Important Notes:

- The Front 60 that works with this kit is from Ford F-250 and F-350 trucks from model years 2005 and up (coil spring). This truss is not intended for newer axles due to different differential offsets.

- Trimming of the factory differential casting may be necessary (see instructions). Other fabrication and modifications may be needed due to variances in lift kits and other factors. Removal of passenger side leaf spring perch is necessary.

- Due to the larger casting on the 60 differential, the Lower Control Arm (LCA) brackets are wider than factory location (41.5 inch Center to Center). Modifications to your Lower Control Arms will likely be necessary. If you have adjustable arms with flexible style joints (heims, Johnny Joints, etc), modifications may not be necessary. Upper Control Arm (UCA) brackets are also slightly higher than factory so adjustable arms may be necessary. The shock mounts are also slightly higher (1.25 inch) than stock to clear the lower control arms.

- This kit does not include any parts for ABS sensors. It is only a bracket kit. Hooking up and configuring these sensors is the responsibility of the end user.

- 60 axles Do Not Match the factory JK 5 lug wheel bolt pattern. New wheels will need to be purchased to do this swap. Brake and Steering components Not Included in this product, but will be available soon.

- This will likely require bumpstop extensions and a new trackbar since the steering is different on this axle from factory axle. The trackbar bracket is higher than stock location to allow proper steering geometry.

Product Videos

Vehicle Fitments

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

These heavy duty inner C gussets are designed to take serious abuse and reinforce your front Dana 30 or 44 JL or JT Inner C's. The 3/16" thick precision cut and formed components precisely contour and wrap around your inner c and add rigidity.

Note: Jeep offers many different variations on which inner c's are offered on their vehicles. Please refer to the following diagram for details on which version to choose. If you have one model of a JL but have swapped in axles from another model, choose the model that the axles were originally in.

JL4505 - Use on JL Rubicon (US/Canada), JT Rubicon (All countries), Sport MaxTow

JL4506 - Use on JL Sport/Sahara, JT Sport/Overland (US/Canada), JL Rubicon (Non-US/Canada)

Details:

- 3/16 inch mild steel

- Precision CNC cut and bent for great fitment

- Precision fit that wraps around axle inner C not just adds a flat gusset

- Provides valuable reinforcement to an area prone to abuse and flex

- Fits: JL Sport/Sahara, JT Sport/Overland (US/Canada), JL Rubicon (Non-US/Canada)

- Sold As: Pair

Note: This kit requires general welding and fabrication skills. Welding should only be done by a competent welder. Artec Industries implies no guarantees or warranties and is not liable for improper installation.

Vehicle Fitments

- Jeep Wrangler 2018 to 2025

- Jeep Gladiator 2020 to 2020

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

Toyota Tacoma 3rd Gen Venture Series Bumper. The factory look but packed with all the good stuff you need, Replaces 3rd Generation Toyota Tacoma factory center section of the bumper

- Low profile design mimics the looks of the factory bumper

- Made From CNC laser cut 3/4 inch, 3/16 inch and 1/8 inch thick steel and CNC formed for great fit and high strength

- Designed from ultra-precise 3D scans and factory CAD files for great and ultra precise fit with no large gaps

- 3/4 inch thick Recovery Tabs located higher than most for better ground clearance

- Recessed Hawse Fairlead Mount for Synthetic Rope to keep winch components protected

- Not Compatible with Steel Cable Roller Fairleads

- Fits Single row 30 inch light bar (SR series, not Radiance or E-Series). Developed using Rigid SR series and works with other similar styles.

- Fits most non-integrate solenoid winches and some integrated solenoid winches including Warn Zeon series

- Winch access holes make it easy to use your winch

- Large Frame plate gussets transfer front of bumper directly to frame

- Includes condenser line relocation brackets

- Multiple winch mounting holes for different offset winches

- Black Powdercoat

- Made In USA

Requires some trimming of OEM plastic bumper and relocation of AC condenser lines depending on winch configuration. Please refer to install guide for trimming locations. Artec not responsible for improper trimming.

Check Application Guide tab for confirmed fitting winches

Requires use of Synthetic Rope Winch due to Hawse Fairlead fitment requirements. Not compatible with Hawse fairleads with large protrusions.

Vehicle Fitments

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

Toyota Tacoma 3rd Gen Venture Series Bumper. The factory look but packed with all the good stuff you need, Replaces 3rd Generation Toyota Tacoma factory center section of the bumper

- Low profile design mimics the looks of the factory bumper

- Made From CNC laser cut 3/4 inch, 3/16 inch and 1/8 inch thick steel and CNC formed for great fit and high strength

- Designed from ultra-precise 3D scans and factory CAD files for great and ultra precise fit with no large gaps

- 3/4 inch thick Recovery Tabs located higher than most for better ground clearance

- Recessed Hawse Fairlead Mount for Synthetic Rope to keep winch components protected

- Not Compatible with Steel Cable Roller Fairleads

- Fits Single row 30 inch light bar (SR series, not Radiance or E-Series). Developed using Rigid SR series and works with other similar styles.

- Fits most non-integrate solenoid winches and some integrated solenoid winches including Warn Zeon series

- Winch access holes make it easy to use your winch

- Large Frame plate gussets transfer front of bumper directly to frame

- Includes condenser line relocation brackets

- Multiple winch mounting holes for different offset winches

- Bare Steel

- Made In USA

Requires some trimming of OEM plastic bumper and relocation of AC condenser lines depending on winch configuration. Please refer to install guide for trimming locations. Artec not responsible for improper trimming.

Check Application Guide tab for confirmed fitting winches

Requires use of Synthetic Rope Winch due to Hawse Fairlead fitment requirements. Not compatible with Hawse fairleads with large protrusions.

Vehicle Fitments

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

Toyota Tacoma 3rd Gen Venture Rear Bumper. Heavy Duty and High Clearance with Extra Skid Plate Protection. Replaces 3rd Generation Toyota Tacoma factory rear bumper

- High Clearance design hugs frame and provides better departure angle

- Bumper made from CNC laser cut 3/4 inch, 3/16 inch and 1/8 inch thick steel

- Skid Plates made from 3/16 inch aluminum for lower weight yet high protection

- Skid Plates protect factory backup sensors which are not cheap to replace

- Countersunk skid hardware provides a smooth surface to prevent bolts getting hung up on rocks

- CNC formed for great fit and high strength

- Designed from ultra-precise 3D scans and factory CAD files for great and ultra precise fit with no large gaps

- 3/4 inch thick Recovery Tabs located higher than most for better ground clearance

- Integrates with factory hitch

- LED license plate lights included

- Includes slotted step plate for grip

- Includes bracket and cutouts for Rigid Ignite backup light (part 20641)

- Large Frame plate gussets transfer front of bumper directly to frame

- Press nuts included for easy installation

- Bare Steel. Aluminum Skid Plates not offered powdercoated.

- Made In the USA

Requires removal of parking sensors from factory bumper. Does not have provisions for blind spot monitoring (BSM) sensors.

Vehicle Fitments

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

Toyota Tacoma 3rd Gen Venture Rear Bumper. Heavy Duty and High Clearance with Extra Skid Plate Protection. Replaces 3rd Generation Toyota Tacoma factory rear bumper

- High Clearance design hugs frame and provides better departure angle

- Bumper made from CNC laser cut 3/4 inch, 3/16 inch and 1/8 inch thick steel

- Skid Plates made from 3/16 inch aluminum for lower weight yet high protection

- Skid Plates protect factory backup sensors which are not cheap to replace

- Countersunk skid hardware provides a smooth surface to prevent bolts getting hung up on rocks

- CNC formed for great fit and high strength

- Designed from ultra-precise 3D scans and factory CAD files for great and ultra precise fit with no large gaps

- 3/4 inch thick Recovery Tabs located higher than most for better ground clearance

- Integrates with factory hitch

- LED license plate lights included

- Includes slotted step plate for grip

- Includes bracket and cutouts for Rigid Ignite backup light (part 20641)

- Large Frame plate gussets transfer front of bumper directly to frame

- Press nuts included for easy installation

- Black Textured Powdercoat for the main bumper. Aluminum Skid Plates not offered powdercoated.

- Made In the USA

Requires removal of parking sensors from factory bumper. Does not have provisions for blind spot monitoring (BSM) sensors.

Vehicle Fitments

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

Toyota Tacoma 3rd Gen A-Arm Skids heeavy duty yet light weight protection for your vulnerable Lower A-arms.

Details:

- Fits 3rd Generation Toyota Tacomas

- Lifetime Warranty on welds, cracking, or bending (Not on scratches...that's what a skid plate does. Original purchaser only).

- Made From 1/4 inch thick aerospace grade 6061 Aluminum - tougher grade than most competitors 5052 aluminum

- With nearly a decade of testing in Ultra 4 racing, competitive rock crawling, and extreme-use Jeeps, Artec Aluminum Skid Plates are proven to take abuse

- Designed from factory CAD files for great and ultra precise fit.

- CNC laser cut and CNC formed from one piece using custom rolled dies for high strength, unique look, and perfect contour fitment to OEM components.

- All bolts under skid plate are countersunk for absolutely smooth bottom

- Bolts directly to OEM Lower A Arm using heavy duty flat head bolts

- Protects Lower A Arm and Lower Suspension components

- TIG welded inside and outside for maximum strength

- Only Adds 7 LBS to the vehicles unsprung weight

- No sacrifice of ground clearance skid contours to the shape of the Lower A arm

- Sold As: Pair

Vehicle Fitments

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

Take your Toyota up a level. Premium Aluminum Link Kit for the 2003+ 4Runner, 2007+ FJ Cruiser, 2008+ 200 Series Land Cruiser, and 2003+ Lexus GX

This kit is a great replacement for weak factory upper and lower control arms and is designed to correct vehicle geometry after lifting the vehicle. The double adjustable ends mean you can use this on nearly any height of lift kit.

These links are light, strong and have been engineer to increase off-road ride quality and performance. The polished aluminum also stands out contrasted to the dark vehicle frame for a high end look.

The 4Runner 5th Gen Aluminum Rear Link Kit starts with our 2.0 inch outer diameter, aerospace grade 7075 Aluminum lower links and 1.5 inch OD upper links.

The aluminum links are out-fitted with time-tested Rock Krawler brand Krawler Joints with a 1.25 inch thread on the lowers and 7/8 inch thread on the uppers with matching jam nuts.

These are the same joints shipped in nearly every Rock Krawler lift kit so you know they stand up to the test of time and abuse...not to mention there are millions of them on the streets.

Each link is threaded with both a Right Hand thread and a Left Hand thread at opposite ends so it is easy to adjust the length for fine tuning. We've also included wrench flats on each end of the aluminum link so you can easily tighten your jam nuts without marring the aluminum.

The real advantage of our aluminum link suspensions is the weight savings. Each link only weighs a few pounds versus steel links which can be dozens of pounds. This weight savings means better fuel mileage, less wear and tear on your vehicle and it's components, easier install and less maintenance.

Aluminum also is naturally rust resistant so you don't have to continually paint them if you scratch them plus aluminum's natural shininess adds so much curb appeal to your vehicle.

A big benefit to 7075 aluminum also is that the material has a memory and will return to its natural straight shape after taking a big hit. While steel control arms will dent and stay bent, 7075 aluminum will remain straight for years and years of constant beating.

This is most important on lower links that really take the hits on rocks.

Springs, shocks, limit straps, sway bar extensions, and extended brake lines are not included in this kit and will be needed.

Two upper links and Two lower links are included in this kit.

- Track bar Available for Purchase separatley and is only for use in Lifted Vehicles:

- 2 - RH, 2 - LH - 1.25 inch -12 tpi x 9/16 inch hole Rock Krawler Joints

- 2 - RH, 2 - LH - 1.25 inch -12 tpi Jam Nuts

- 2 - RH, 2 - LH - 7/8 inch -14 tpi x 12mm hole Rock Krawler Joints

- 2 - RH, 2 - LH - 7/8 inch -14 tpi Jam Nuts

- 2 - 2.0 inch OD 7075-T6 Polished Aluminum Lower Links

- 2 - 1.5 inch OD 7075-T6 Polished Aluminum Upper Links

- 4 - 9/16 inch bolts, washers, and lock nuts

Vehicle Fitments

- Toyota Land Cruiser 2003 to 2021

- Toyota FJ Cruiser 2007 to 2014

- Toyota 4Runner 2003 to 2021

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

Take your Toyota up a level. Premium Aluminum Link Kit for the 2003+ 4Runner, 2007+ FJ Cruiser, 2008+ 200 Series Land Cruiser, and 2003+ Lexus GX

This kit is a great replacement for weak factory upper and lower control arms and is designed to correct vehicle geometry after lifting the vehicle. The double adjustable ends mean you can use this on nearly any height of lift kit.

These links are light, strong and have been engineer to increase off-road ride quality and performance. The polished aluminum also stands out contrasted to the dark vehicle frame for a high end look.

The 4Runner 5th Gen Aluminum Rear Link Kit starts with our 2.0 inch outer diameter, aerospace grade 7075 Aluminum lower links and 1.5 inch OD upper links.

The aluminum links are out-fitted with time-tested Rock Krawler brand Krawler Joints with a 1.25 inch thread on the lowers and 7/8 inch thread on the uppers with matching jam nuts.

These are the same joints shipped in nearly every Rock Krawler lift kit so you know they stand up to the test of time and abuse...not to mention there are millions of them on the streets.

Each link is threaded with both a Right Hand thread and a Left Hand thread at opposite ends so it is easy to adjust the length for fine tuning. We've also included wrench flats on each end of the aluminum link so you can easily tighten your jam nuts without marring the aluminum.

The real advantage of our aluminum link suspensions is the weight savings. Each link only weighs a few pounds versus steel links which can be dozens of pounds. This weight savings means better fuel mileage, less wear and tear on your vehicle and it's components, easier install and less maintenance.

Aluminum also is naturally rust resistant so you don't have to continually paint them if you scratch them plus aluminum's natural shininess adds so much curb appeal to your vehicle.

A big benefit to 7075 aluminum also is that the material has a memory and will return to its natural straight shape after taking a big hit. While steel control arms will dent and stay bent, 7075 aluminum will remain straight for years and years of constant beating.

This is most important on lower links that really take the hits on rocks.

Springs, shocks, limit straps, sway bar extensions, and extended brake lines are not included in this kit and will be needed.

- Only Track Bar Is Included in this Kit. Only for use with lifted vehicle, not stock height

Vehicle Fitments

- Toyota Land Cruiser 2003 to 2021

- Toyota FJ Cruiser 2007 to 2014

- Toyota 4Runner 2003 to 2021

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

This kit is a great replacement for weak factory upper and lower control arms and is designed to correct vehicle geometry after lifting the vehicle. The double adjustable ends mean you can use this on nearly any height of lift kit.

These links are light, strong and have been engineer to increase off-road ride quality and performance. The polished Aluminum also stands out contrasted to the dark vehicle frame for a high end look.

The 4Runner 5th Gen Aluminum Rear Link Kit starts with our 2.0 inch outer diameter, aerospace grade 7075 Aluminum lower links and 1.5 inch OD upper links. The Aluminum links are out-fitted with time-tested Rock Krawler brand Krawler Joints with a 1.25 inch thread on the lowers and 7/8 inch thread on the uppers with matching jam nuts.

These are the same joints shipped in nearly every Rock Krawler lift kit so you know they stand up to the test of time and abuse...not to mention there are millions of them on the streets. Each link is threaded with both a Right Hand thread and a Left Hand thread at opposite ends so it is easy to adjust the length for fine tuning. We've also included wrench flats on each end of the Aluminum link so you can easily tighten your jam nuts without marring the Aluminum.

The real advantage of our Aluminum link suspensions is the weight savings. Each link only weighs a few pounds versus steel links which can be dozens of pounds. This weight savings means better fuel mileage, less wear and tear on your vehicle and it's components, easier install and less maintenance. Aluminum also is naturally rust resistant so you don't have to continually paint them if you scratch them plus Aluminum's natural shininess adds so much curb appeal to your vehicle.

A big benefit to 7075 Aluminum also is that the material has a memory and will return to its natural straight shape after taking a big hit. While steel control arms will dent and stay bent, 7075 Aluminum will remain straight for years and years of constant beating. This is most important on lower links that really take the hits on cks.

Notes:

- Springs, shocks, limit straps, sway bar extensions, and extended brake lines are not included in this kit and will be needed.

- Two Upper Links, Two Lower Links, And Track Bar Are Included In This Kit. Track Bar Only Used In Vehicles With A Lift, Not Stock Height.

Included in this Kit:

- 2 - RH, 2 - LH - 1.25 inch -12 tpi x 9/16 inch hole Rock Krawler Joints

- 2 - RH, 2 - LH - 1.25 inch -12 tpi Jam Nuts

- 2 - RH, 2 - LH - 7/8 inch -14 tpi x 12mm hole Rock Krawler Joints

- 3 - RH, 3 - LH - 7/8 inch -14 tpi Jam Nuts

- 1 - RH, 1 - LH - 7/8 inch -14 tpi JMX Pro Rod Ends

- 4 - 7/8 inch x 14 mm High Misalignment Spacers

- 2 - 2.0 inch OD 7075-T6 Polished Aluminum Lower Links

- 2 - 1.5 inch OD 7075-T6 Polished Aluminum Upper Links

- 1 - 1.5 inch OD 7075-T6 Polished Trackbar Link

- 4 - 9/16 inch bolts, washers, and lock nuts

Fits:

- 2003-Present Toyota 4-Runner

- 2007-Present Toyota FJ Cruiser

- 2008-Present 200 Series Land Cruiser

- 2003-Present Lexus GX

Product Videos

Vehicle Fitments

- Toyota Land Cruiser 2003 to 2021

- Toyota FJ Cruiser 2007 to 2014

- Toyota 4Runner 2003 to 2021

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

Heavy Duty yet Light weight protection for your vulnerable Lower A-arms. With nearly a decade of testing in Ultra 4 racing, competitive rock crawling, and extreme-use Jeeps, Artec Aluminum Skid Plates are proven to take abuse.

Features:

- Fits 5th Generation Toyota 4Runners 2010-2018

- Lifetime Warranty on welds, cracking, or bending (Not on scratches, that's what a skid plate does. Original purchaser only).

- Made From 1/4 inch thick aerospace grade 6061 Aluminum-tougher grade than most competitors 5052 aluminum

- With nearly a decade of testing in Ultra 4 racing, competitive rock crawling, and extreme-use Jeeps, Artec Aluminum Skid Plates are proven to take abuse

- Designed from factory CAD files for great and ultra precise fit.

- CNC laser cut and CNC formed from ONE PIECE using custom rolled dies for high strength, unique look, and perfect contour fitment to OEM components.

- All bolts under skid plate are countersunk for absolutely smooth bottom

- Bolts directly to OEM Lower A Arm using heavy duty flat head bolts

- Protects Lower A Arm and Lower Suspension components

- TIG welded inside and outside for maximum strength

- Only Adds 7 LBS to the vehicles unsprung weight

- No sacrifice of ground clearance skid contours to the shape of the Lower A arm

Product Videos

Vehicle Fitments

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

Toyota 4Runner 5th Gen Venture Series Bumper. The factory look but packed with all the good stuff you need. Designed from factory CAD files for great and ultra precise fit with no large gaps.

Features:

- Replaces 5th Generation Toyota 4Runner factory center section of the bumper

- Low profile design mimics the looks of the factory bumper

- Made From CNC laser cut 3/4 inch, 3/16 inch and 1/8 inch thick steel and CNC formed for great fit and high strength

- Designed from factory CAD files for great and ultra precise fit with no large gaps

- 3/4 inch thick Recovery Tabs located higher than most for better ground clearance

- Recessed Fairlead Mount to keep winch components protected

- Fits Single row 30 inch light bar

- Fits most non-integrate solenoid winches and some integrated solenoid winches including Superwinch EXP and Warn Zeon series

- Winch access holes make it easy to use your winch

- Frame plate hooks make it easy to mount your bumper for mockup and bolting on

- Large Frame plate gussets transfer front of bumper directly to frame

- Multiple winch mounting holes for different offset winches

- Available in Bare Steel

- Made in USA

- Finish: Bare

- Material: Steel

- Sold As: Each

Vehicle Fitments

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

Superduty Aluminum High Steer Arm. Artec Industries is excited to announce our new 7075 Aluminum high steer arm for '05-'12 Ford Superduty F-250 and F-350 trucks.

This high steer arm is for use with the aftermarket Reid Racing Superduty knuckle available. Together, this arm and knuckle allow the user to correct steering problems that are common on lifted Superduties or provide a steering solution for our popular Superduty Axle Swap kits for Jeep TJ, JK, JL, and JT.

- CNC machined from 1 inch thick 7075 high strength Aluminum and clear anodized for corrosion resistance

- Analysis shows equal or greater strength than equivalent steel version at half the weight

- For use only on Reid Racing Superduty Knuckle Passenger Side

- Sold by itself or bundled with stainless steel spacer adapters for 3/4 inch hole, 14 mm hole, 18 mm hole or Ford 1-ton tapered drag link end

- Hole in arm is 1.0 inch diameter which allows you to make custom spacer adapters if you'd like

- Uses high strength 1/2 inch ARP studs and acorn nuts available as an add-on

- Corrects OEM steering geometry allowing drag link to mount above or under the arm depending on lift height

- Compatible with our JK, JL, JT 1-ton swap bracket kit for 2005+ Superduty axles

Note: This is a passenger side arm only.

Uses D60 ARP Studs And Nuts 5 Pack Kit.

Trackbar bracket modifications necessary when changing Ford Superduty OEM steering geometry. Jeep trackbar modifications may also be necessary.

Optional spacers that fit into the 1.0 inch hole on the end of the arm.

Choose 3/4 inch straight hole for rod ends using a 3/4 inch bolt, 18mm straight hole for RockKrawler tie rod ends, 14mm hole for SteerSmarts tie rod ends, Tapered Ford hole for 1-ton Ford Drag Link end ES3417T

Vehicle Fitments

- Ford F-350 Super Duty 2005 to 2012

- Ford F-250 Super Duty 2005 to 2012

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

ARTEC JL Front Fender Chop Kit Brackets. Did you remove the bottom half of your Rubicon Fenders for clearance, only to lose your turn/marker lights and are left with a floppy factory fender? Artec Industries is excited to announce our new JL Front Fender Chop Kit Brackets which not only reinforce your factory upper half Rubicon fenders after you've removed the lower half, they also give you mounting locations for new turn signal and marker lights.

Our brackets are constructed from rigid 1/8 inch thick steel and designed using State of the Art 3D modeling with files directly from the manufacturer for a precise fit. These brackets are hard powdercoated black for direct bolt-on installation and a long life.

Features:

- Designed for OEM Rubicon fender flares with the lower half of the flare removed (other models to follow)

- 1/8 inch steel brackets add rigidity back to upper flare half

- Holes included for mounting Marker/Turn lights (optional not included)

- Designed using original OEM files and CNC laser cut and CNC bent in-house for precise fit

- Includes new hardware for mounting the brackets