Artec Industries

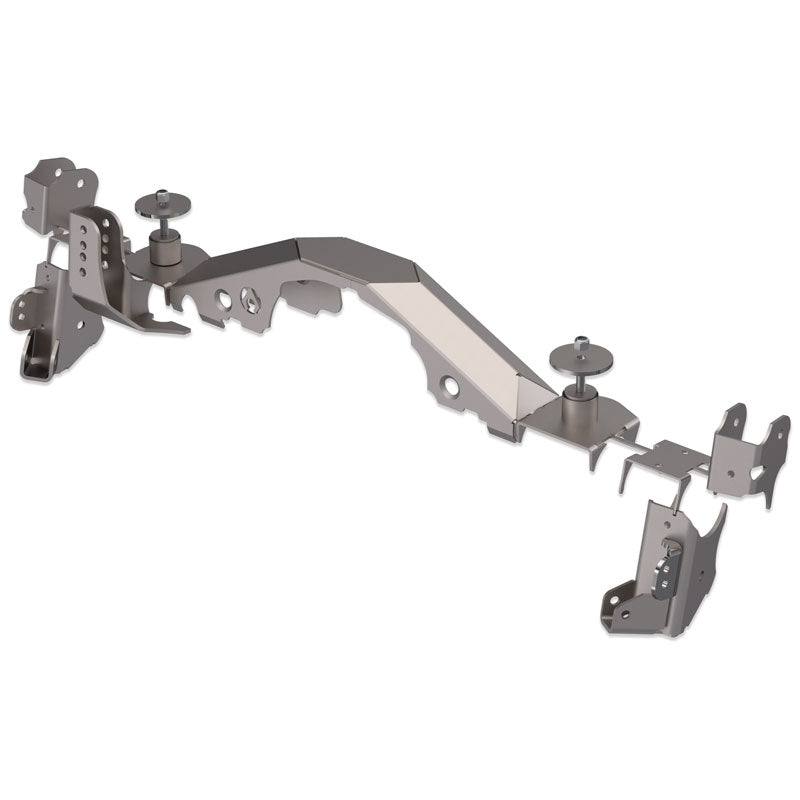

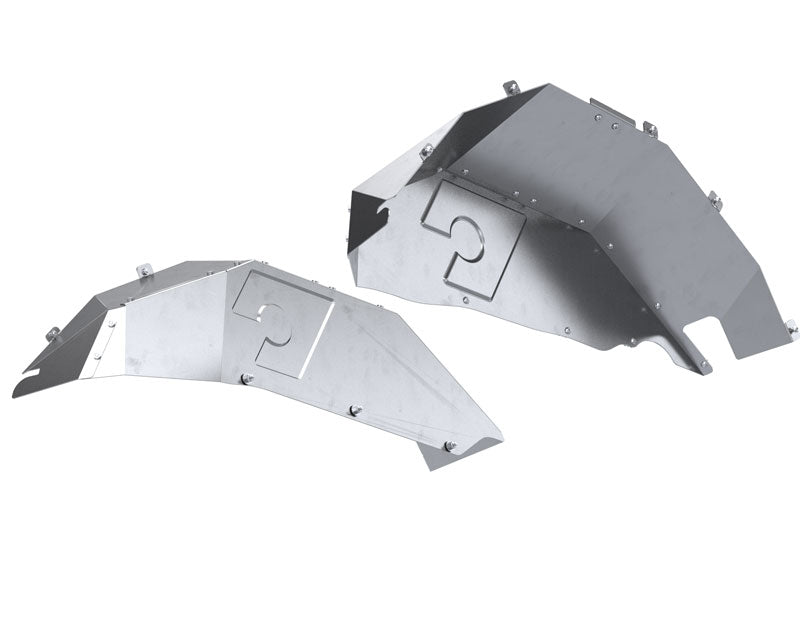

JK 1 Ton Basics Rear Axle Swap Kit with Truss. All the brackets and truss necessary for swapping in a 1 ton rear axle into a Jeep JK Wrangler ('07-'18).

Artec Industries is excited to announce the JK 1 Ton Basics Rear Axle Swap Kit with Truss. This is a basic bracket system which can be used on practically any axle with a 3.5 inch axle tube (or similar).

This kit provides the factory link, trackbar, spring, anti-sway bar, bump stop pads and shock locations. The kit includes a template for correctly spacing your brackets off the differential casting for AAM 10.5 inch 14 bolt axles and Sterling 10.5 axles found in Ford Superduty.

Other axles can be used as well, just make sure they are wide enough to fit the upper control arm brackets and you have a plan for mounting the ABS sensors.

Features include:

- Using a 1 ton axle will support larger tires and less chance of breakage in extreme conditions

- APEX Truss CNC laser cut from 3/16 inch steel and CNC bent for a precise fit

- Brackets CNC laser cut from 1/4 inch, 3/16 inch and 1/8 inch steel for high strength and precision and CNC bent for great fitment.

- Includes all the brackets necessary for a complete axle swap including upper and lower control arm mounts, shock mounts, anti-sway bar mounts, trackbar mount, bumpstop pads and coil spring mounts.

- Save hours of installation time. Coil brackets are offset from differential casting using include template. All other brackets line up to each other, no guessing and measuring involved.

- Tracbar mount includes 4 locations for those who have aftermarket lifts. Stock height hole is not included though.

- Easily upgradeable for future link geometry changes. Just trim off factory location upper control mounts and weld on a truss and center link mount (not included)

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

JK 1 Ton Basics Rear Axle Swap Kit with Truss. All the brackets and truss necessary for swapping in a 1 ton rear axle into a Jeep JK Wrangler ('07-'18).

Artec Industries is excited to announce the JK 1 Ton Basics Rear Axle Swap Kit with Truss. This is a basic bracket system which can be used on practically any axle with a 3.5 inch axle tube (or similar).

This kit provides the factory link, trackbar, spring, anti-sway bar, bump stop pads and shock locations. The kit includes a template for correctly spacing your brackets off the differential casting for AAM 10.5 inch 14 bolt axles and Sterling 10.5 axles found in Ford Superduty.

Other axles can be used as well, just make sure they are wide enough to fit the upper control arm brackets and you have a plan for mounting the ABS sensors.

Features include:

- Using a 1 ton axle will support larger tires and less chance of breakage in extreme conditions

- APEX Truss CNC laser cut from 3/16 inch steel and CNC bent for a precise fit

- Brackets CNC laser cut from 1/4 inch, 3/16 inch and 1/8 inch steel for high strength and precision and CNC bent for great fitment.

- Includes all the brackets necessary for a complete axle swap including upper and lower control arm mounts, shock mounts, anti-sway bar mounts, trackbar mount, bumpstop pads and coil spring mounts.

- Save hours of installation time. Coil brackets are offset from differential casting using include template. All other brackets line up to each other, no guessing and measuring involved.

- Tracbar mount includes 4 locations for those who have aftermarket lifts. Stock height hole is not included though.

- Easily upgradeable for future link geometry changes. Just trim off factory location upper control mounts and weld on a truss and center link mount (not included)

Important Note for 14 Bolt: The 14 bolt axle is available in a variety of vehicles over several decades. In order for the JK swap to work with factory UCA brackets, the correct width axle must be used.

If you are not using factory UCA brackets, but rather a 3-link style system mounted on the truss, you can choose any width axle you need but take care to ensure its width is close to the front axle. Older 14 bolt axles will not work with ABS brackets we offer either.

This Kit Is Intended For Use With A Newer Style 14 Bolt Axle With Ribbing On The Casting (As Shown) And Has A Wms-Wms Measurement Of 68 Inch Or Greater.

This axle is referred to as an AAM 14 bolt 10.5 inch ring gear and is found in '99-'06 GM 2500 and 3500 SRW trucks. Van axles have a different differential offset and will not align the truss correctly.

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

JK 1 Ton Basics Rear Axle Swap Kit with Truss. All the brackets and truss necessary for swapping in a 1 ton rear axle into a Jeep JK Wrangler ('07-'18).

Artec Industries is excited to announce the JK 1 Ton Basics Rear Axle Swap Kit with Truss. This is a basic bracket system which can be used on practically any axle with a 3.5 inch axle tube (or similar).

This kit provides the factory link, trackbar, spring, anti-sway bar, bump stop pads and shock locations. The kit includes a template for correctly spacing your brackets off the differential casting for AAM 10.5 inch 14 bolt axles and Sterling 10.5 axles found in Ford Superduty.

Other axles can be used as well, just make sure they are wide enough to fit the upper control arm brackets and you have a plan for mounting the ABS sensors.

Features include:

- Using a 1 ton axle will support larger tires and less chance of breakage in extreme conditions

- APEX Truss CNC laser cut from 3/16 inch steel and CNC bent for a precise fit

- Brackets CNC laser cut from 1/4 inch, 3/16 inch and 1/8 inch steel for high strength and precision and CNC bent for great fitment.

- Includes all the brackets necessary for a complete axle swap including upper and lower control arm mounts, shock mounts, anti-sway bar mounts, trackbar mount, bumpstop pads and coil spring mounts.

- Save hours of installation time. Coil brackets are offset from differential casting using include template. All other brackets line up to each other, no guessing and measuring involved.

- Tracbar mount includes 4 locations for those who have aftermarket lifts. Stock height hole is not included though.

- Easily upgradeable for future link geometry changes. Just trim off factory location upper control mounts and weld on a truss and center link mount (not included)

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

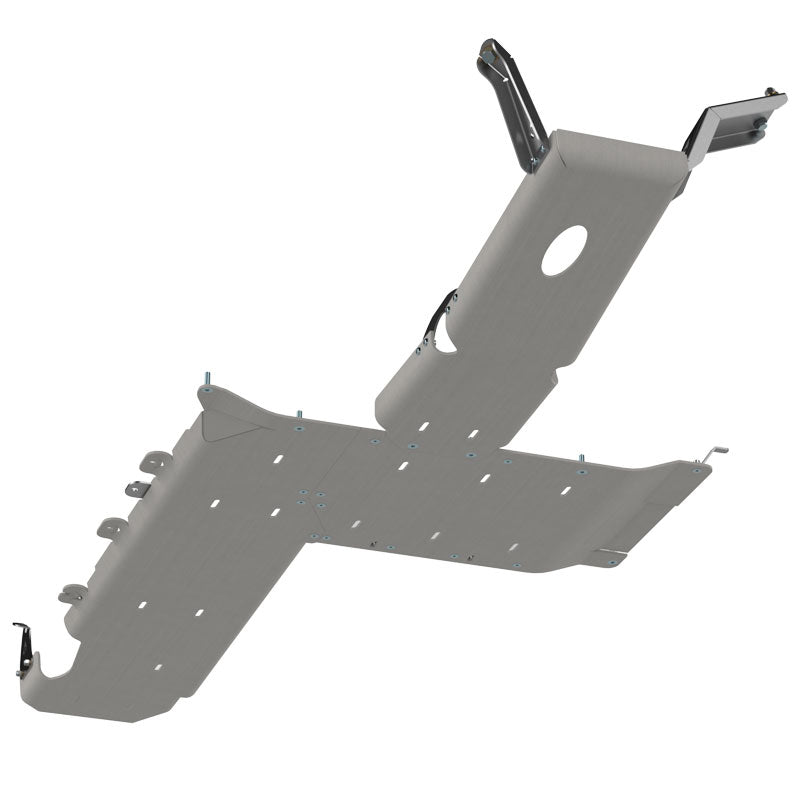

Jeep JK 1 Ton APEX Rear 9 bolt Truss Swap Kit. The new APEX Truss and Brackets for swapping in a 9 bolt 10.5 rear axle into a Jeep JK Wrangler ('07-'18)

Stronger Design, Lighter Weight, Easier Install.

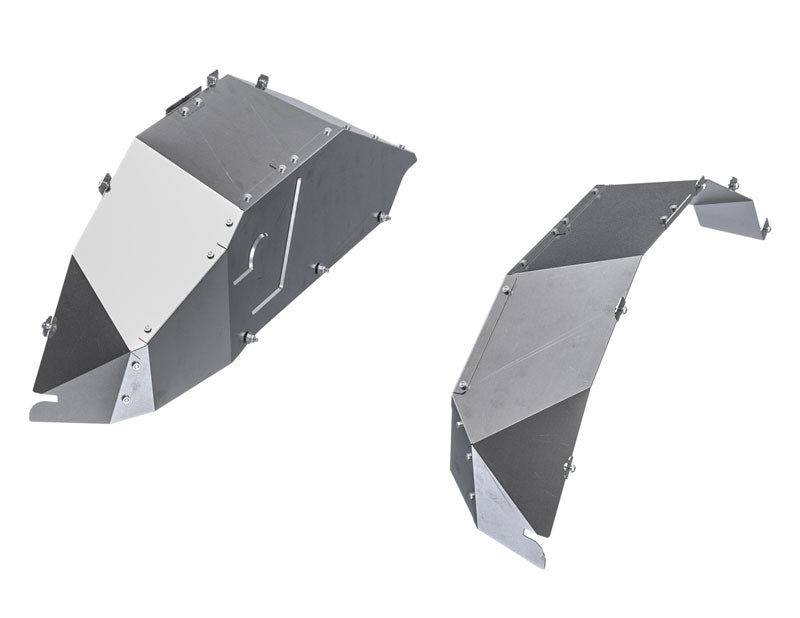

A new era has begun with the arrival of the APEX Truss! Artec Industries is proud to announce the next generation of Patent Pending axle trusses

This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the APEX truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams.

Previous version with long weld seams which can be lead to extra weld warping of the axle, longer install times and can be inconsistent. Without long seams to weld, now you drop the truss directly on to the axle and weld it to the axle faster.

Artec Industries is excited to announce the JK 1 Ton APEX Rear 9 inch Truss Swap Kit. This is an advanced truss and bracket system which can be used for Spidertrax 3.5 inch Ultimate or Pro series Housing.

This kit provides the factory link, trackbar, spring, anti-sway bar, bump stop pads and shock locations all encompassed in an axle tube reinforcing truss system.

Features include:

- Patent Pending APEX Truss peaked top design provides more rigidity than a flat top truss design

- CNC Precision Laser cut in-house from 1/4 inch and 3/16 inch mild steel for a lightweight yet strong solution...only 42 lbs total

- CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Ford and Jeep for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours both the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- Two piece truss design means smaller packaging and less shipping costs along with easy installation

- Using a 1 ton axle will support larger tires and less chance of breakage in extreme conditions

- Coil brackets and bump stop pads are combined to form an axle tube truss and allows for easy installment of other brackets

- Precision CNC cut from 1/4 inch and 3/16 inch steel for high strength and precision and CNC bent for great fitment.

- Includes all the brackets necessary for a complete axle swap including upper and lower control arm mounts, shock mounts, anti-sway bar mounts, trackbar mount, bumpstop pads and coil spring mounts.

- Save hours of installation time with the built-in axle tube truss which is quicker to weld than individual brackets

- Tracbar mount includes 4 locations for those who have aftermarket lifts. Stock height hole is not included though.

- Coil Spring locator is machined from solid steel making welding to bracket quicker than previous tube and cap style locators

- Easily upgradeable for future link geometry changes. Just trim off factory location upper control mounts and weld on a center link mount (not included)

Note: This kit does not include any parts for ABS sensors. It is only a bracket kit. Hooking up and configuring these sensors is the responsibility of the end user. We will be offering a Housing End to fit our Super Bearings soon.

Most 1 ton axles Do not match the factory JL 5 lug wheel bolt pattern. New wheels will need to be purchased to do this swap. Brake components Not included in this product, but will be available separately shortly

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

Jeep JK 1 Ton APEX Rear 14 bolt Truss Swap Kit. The new APEX Truss and Brackets for swapping in aAAM 14 bolt 10.5 rear axle into a Jeep JK Wrangler ('07-'18)

Stronger Design, Lighter Weight, Easier Install.

A new era has begun with the arrival of the APEX Truss! Artec Industries is proud to announce the next generation of Patent Pending axle trusses

This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the APEX truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams.

Previous version with long weld seams which can be lead to extra weld warping of the axle, longer install times and can be inconsistent. Without long seams to weld, now you drop the truss directly on to the axle and weld it to the axle faster.

Artec Industries is excited to announce the JK 1 ton APEX Rear 14 bolt Truss Swap Kit. This is an advanced truss and bracket system which can be used for AAM 14 bolt 10.5 inch ring gear.

This kit provides the factory link, trackbar, spring, anti-sway bar, bump stop pads and shock locations all encompassed in an axle tube reinforcing truss system. The Sterling axle is a great match to the Superduty Front Dana 60 however there are some considerations to take into account (see below).

Features include:

- Patent Pending APEX Truss peaked top design provides more rigidity than a flat top truss design

- CNC Precision Laser cut in-house from 1/4 inch and 3/16 inch mild steel for a lightweight yet strong solution...only 42 lbs total

- CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Ford and Jeep for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours both the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- Two piece truss design means smaller packaging and less shipping costs along with easy installation

- Using a 1 ton axle will support larger tires and less chance of breakage in extreme conditions

- Coil brackets and bump stop pads are combined to form an axle tube truss and allows for easy installment of other brackets

- Precision CNC cut from 1/4 inch and 3/16 inch steel for high strength and precision and CNC bent for great fitment.

- Includes all the brackets necessary for a complete axle swap including upper and lower control arm mounts, shock mounts, anti-sway bar mounts, trackbar mount, bumpstop pads and coil spring mounts.

- Save hours of installation time with the built-in axle tube truss which is quicker to weld than individual brackets

- Tracbar mount includes 4 locations for those who have aftermarket lifts. Stock height hole is not included though.

- Coil Spring locator is machined from solid steel making welding to bracket quicker than previous tube and cap style locators

- Shock brackets have been moved up for a slightly higher clearance lower control arm bracket

- Easily upgradeable for future link geometry changes. Just trim off factory location upper control mounts and weld on a center link mount (not included)

Important Note for 14 Bolt: The 14 bolt axle is available in a variety of vehicles over several decades. In order for the JK swap to work with factory UCA brackets, the correct width axle must be used. If you are not using factory UCA brackets, but rather a 3-link style system mounted on the truss, you can choose any width axle you need but take care to ensure its width is close to the front axle. Older 14 bolt axles will not work with ABS brackets we offer either.

This Kit Is Intended For Use With A Newer Style 14 Bolt Axle With Ribbing On The Casting (As Shown) And Has A Wms-Wms Measurement Of 68 Inch Or Greater.

This axle is referred to as an AAM 14 bolt 10.5 inch ring gear and is found in '99-'06 GM 2500 and 3500 SRW trucks. Van axles have a different differential offset and will not align the truss correctly.

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

Jeep JK 1 Ton APEX RearSterline Truss Swap Kit. The new APEX Truss and Brackets for swapping in a 9 bolt 10.5 rear axle into a Jeep JK Wrangler ('07-'18)

Stronger Design, Lighter Weight, Easier Install.

A new era has begun with the arrival of the APEX Truss! Artec Industries is proud to announce the next generation of Patent Pending axle trusses

This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the APEX truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams.

Previous version with long weld seams which can be lead to extra weld warping of the axle, longer install times and can be inconsistent. Without long seams to weld, now you drop the truss directly on to the axle and weld it to the axle faster.

Artec Industries is excited to announce the JK 1 ton APEX Rear Sterling Truss Swap Kit. This is an advanced truss and bracket system which can be used for Superduty Sterling 10.5 or 10.2.

This kit provides the factory link, trackbar, spring, anti-sway bar, bump stop pads and shock locations all encompassed in an axle tube reinforcing truss system. The Sterling axle is a great match to the Superduty Front Dana 60 however there are some considerations to take into account

Features include:

- Patent Pending APEX Truss peaked top design provides more rigidity than a flat top truss design

- CNC Precision Laser cut in-house from 1/4 inch and 3/16 inch mild steel for a lightweight yet strong solution...only 42 lbs total

- CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Ford and Jeep for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours both the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- Two piece truss design means smaller packaging and less shipping costs along with easy installation

- Using a 1 ton axle will support larger tires and less chance of breakage in extreme conditions

- Coil brackets and bump stop pads are combined to form an axle tube truss and allows for easy installment of other brackets

- Precision CNC cut from 1/4 inch and 3/16 inch steel for high strength and precision and CNC bent for great fitment.

- Includes all the brackets necessary for a complete axle swap including upper and lower control arm mounts, shock mounts, anti-sway bar mounts, trackbar mount, bumpstop pads and coil spring mounts.

- Save hours of installation time with the built-in axle tube truss which is quicker to weld than individual brackets

- Tracbar mount includes 4 locations for those who have aftermarket lifts. Stock height hole is not included though.

- Coil Spring locator is machined from solid steel making welding to bracket quicker than previous tube and cap style locators

- Easily upgradeable for future link geometry changes. Just trim off factory location upper control mounts and weld on a center link mount (not included)

Important Note for Sterling Axles: The Superduty Rear Axle (Sterling 10.25 and 10.5) is more offset to the passenger side than the factory differential and can result in contact with the gas tank at the pinion.

It is likely you will need to either stretch the rear axle, or use an aftermarket gas tank. By purchasing, you acknowledge you understand potential conflict with the factory gas tank. Artec will not accept returns on modified, welded, or otherwise resell-able products.

Note: This kit does not include any parts for ABS sensors. It is only a bracket kit. Hooking up and configuring these sensors is the responsibility of the end user. We offer ABS brackets and tone rings for 14 bolt and Sterling.

Most 1 ton axles Do not match the factory JK 5 lug wheel bolt pattern. New wheels will need to be purchased to do this swap. Brake components Not included in this product, but will be available separately shortly.

Note: This kit requires general welding and fabrication skills. Welding should only be done by a competent welder who understand different materials. Some welding of cast and mild steel will be used. Artec Industries implies no guarantees or warranties and is not liable for improper installation.

Some grinding and fitment may be required when installing this kit. Every axle varies slightly and some fabrication may be required. Will require brake line relocation to fit.

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

JK 1 TON BASICS Rear Axle Swap Kit. All the brackets necessary for swapping in a 1 ton rear axle into a Jeep JK Wrangler ('07-'17)

Artec Industries is excited to announce the JK 1 ton Basics Rear Axle Swap Kit. This is a basic bracket system which can be used on practically any axle with a 3.5 inch axle tube (or similar). This kit provides the factory link, trackbar, spring, anti-sway bar, bump stop pads and shock locations.

The kit includes a template for correctly spacing your brackets off the differential casting for AAM 10.5 inch 14 bolt axles (see details below) and Sterling 10.5 axles found in Ford Superduty. Other axles can be used as well, just make sure they are wide enough to fit the upper control arm brackets (see diagram below) and you have a plan for mounting the ABS sensors.

This kit Does Not include a truss however we have made it easy to add one in the options menu if you'd like.

Features include:

- Using a 1 ton axle will support larger tires and less chance of breakage in extreme conditions

- Precision CNC cut from 1/4 inch, 3/16 inch and 1/8 inch steel for high strength and precision and CNC bent for great fitment.

- Includes all the brackets necessary for a complete axle swap including upper and lower control arm mounts, shock mounts, anti-sway bar mounts, trackbar mount, bumpstop pads and coil spring mounts.

- Save hours of installation time. Coil brackets are offset from differential casting using include template. All other brackets line up to each other, no guessing and measuring involved.

- Tracbar mount includes 4 locations for those who have aftermarket lifts. Stock height hole is not included though.

- Easily upgradeable for future link geometry changes. Just trim off factory location upper control mounts and weld on a truss and center link mount (not included)

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

UD60 Front APEX Truss Make Your Front Axle More Rigid and prevent tube spin. A new era has begun with the arrival of the APEX Truss! Artec Industries is proud to announce the next generation of Patent Pending axle trusses

This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the APEX truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams.

Previous versions with long weld seams can lead to extra weld warping of the axle, longer install times and can be inconsistent.

The APEX Truss also helps to prevent axle tubes from spinning in the differential which is a known issue on the UD60.

The new UD60 Front APEX Truss is the epitome of low cost, easy and quick to weld, simple, strong, and complete solutions for making your upgraded axle even stronger. You want easy insurance for your axle? The JK APEX Truss provides it.

Features include:

- Patent Pending APEX truss peaked top design provides more rigidity than a flat top truss design

- Truss is CNC Precision Laser cut in-house from 3/16 inch mild steel for a lightweight yet strong solution...only 7 lbs

- Truss is CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Dana Corp and Jeep for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours to the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- Prevents axle tube spinning in the differential...a known issue on the UD60

- Truss strengthens the weakest sections of the axle...around the control arm brackets, and where the tube enters the casting

- Low Profile Design doesn't go over differential and allows usage in vehicles with only slight lift

Note: Dana Spicer offers different variations of this axle housings. Please refer to the following diagram for details on which version to choose. If you have one model of a vehicle but have swapped in axles from another model, choose the model that the axles were originally built for. The main difference is the trackbar bracket. Refer to the images to show the difference.

TR6063 - Use on JK front UD60 axle

TR6064 - Use on JL/JT front UD60 axle

Some grinding and fitment may be required when installing this kit. Every axle varies slightly and some fabrication may be required.

In rare and extreme cases, the truss may come into contact with oil pan. Prior to operating the vehicle, remove the coil springs, cycle the suspension including full compression of both sides simultaneously and add bumpstop extensions to prevent damage to oil pan.

This Kit Is Intended For Vehicles With At Least Minor Lifts (2.0Inch+ Recommended)And At Least 1/2InchBump Stop Extensions. Check Clearances Before Installing. Not Tested In Non-Us Jks Or Right Hand Drive Axles.

Note: This kit requires general welding and fabrication skills including welding to the cast center section. Welding should only be done by a competent welder. Artec Industries implies no guarantees or warranties and is not liable for improper installation

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

JK APEX Front Axle Truss - A new era has begun with the arrival of the APEX Truss! Artec Industries is proud to announce the next generation of Patent Pending axle trusses. This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the APEX truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous versions with long weld seams can be lead to extra weld warping of the axle, longer install times and can be inconsistent.

This peaked structure not only applies to the axle tube between the coil perches but extends underneath the coil perches as well, forming a complete truss from end to end of axle, an industry first in an OEM axle application. The JK APEX Front Axle Truss has been secretly tested for over a year and a half proving that even though the truss is lighter weight, the peaked structure of the truss holds up to both extreme applications and daily driving.

The new JK APEX Front Axle Truss is the epitome of low cost, easy and quick to weld, simple, strong, and complete solutions for making your factory Jeep axle take more abuse than originally intended. You want easy insurance for your axle? The JK APEX Truss provides it.

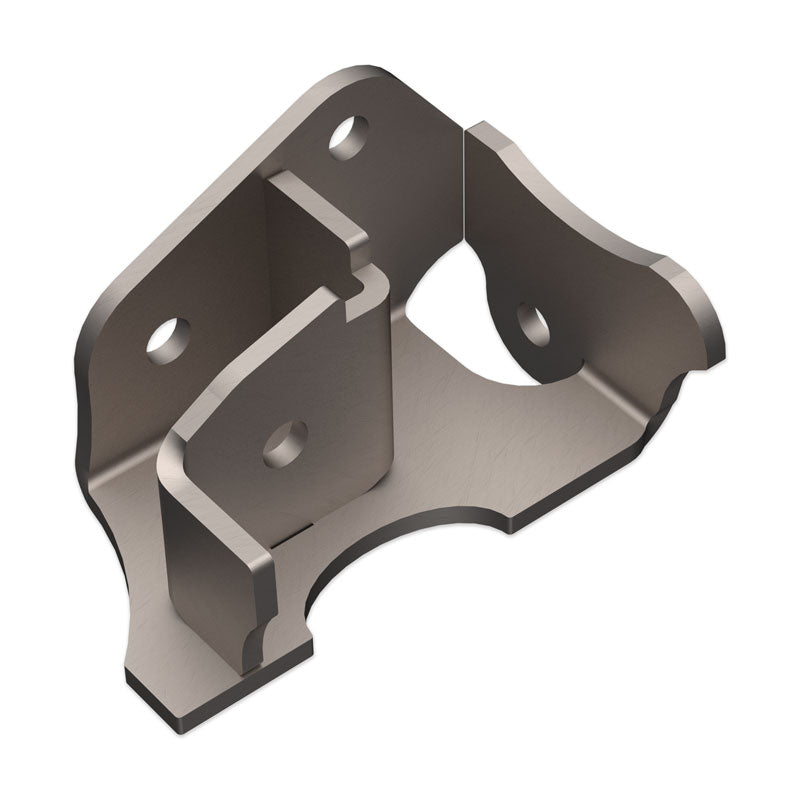

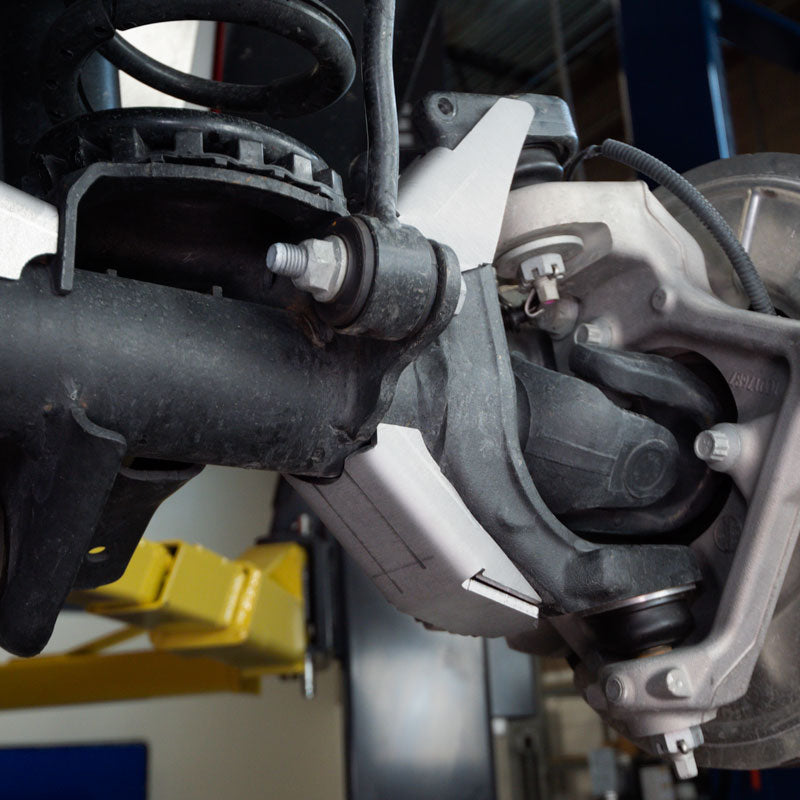

JK Front LCA Skids - These heavy duty skids are designed to take serious abuse and reinforce your JL front axle lower control arm brackets. The 1/4 inch thick precision cut and formed components of this setup mean they'll install easily and protect your brackets and lower control arms.

JK Inner C Gussets - These heavy duty inner C gussets are designed to take serious abuse and reinforce your front Dana 30 or 44 JK Inner C's. The 1/4 inch thick precision cut and formed components precisely contour and wrap around your inner c and add rigidity.

JK APEX Trackbar Brackets - One of the weakest components of your factory axle is the axle side tracbar bracket and it's typically one of the main reasons for death wobble. Our new Heavy Duty Tracbar brackets are designed to work with our new APEX Truss and eliminate the issues caused by weak factory brackets.

They are seriously beefy and ready to take the abuse not to mention raise your steering stabilizer up and out of the way of rocks. For those running smaller lifts and are using an adjustable tracbar mounting to the the factory location, choose Stock Height. For those with taller lifts that require a Drag Link Flip, choose Raised Height.

How is this better than the Regular Armor Kit? This Kit includes entire replacement LCA brackets and Shock brackets whereas the regular Armor Kit just adds a skid plate to the factory LCA brackets.

Included in this kit:

- APEX Front Axle Truss

- Front LCA Skids

- Inner C Gussets

- APEX Heavy Duty Trackbar Bracket

Features include:

- Patent Pending APEX truss peaked top design provides more rigidity than a flat top truss design

- Truss is CNC Precision Laser cut in-house from 1/8 inch mild steel for a lightweight yet strong solution...only 7 lbs

- Truss is CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Dana Corp and Jeep for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- APEX design continues under the OEM coil buckets for complete end-to-end axle reinforcement...an industry first

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours to the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- Provides worry-free wheeling of up to 37 inch tires on stock JK axles

- Truss strengthens the weakest sections of the axle...under the coil perches, around the control arm brackets, and where the tube enters the casting

- Low Profile Design doesn't go over differential and allows usage in vehicles with only slight lift

- Front LCA Skids, Inner C Gussets and HD Trackbar Brackets made from 1/4 inch steel

- Skids, Gussets, and Brackets strengthen or replace weak components of the axle that are prone to failure

- Raised Trackbar

Note: Jeep offers different variations of axle housings. Please refer to the following diagram for details on which version to choose. If you have one model of a vehicle but have swapped in axles from another model, choose the model that the axles were originally in.

JK3055 - Use on JK Sport/Sahara (Dana 30 front axle) with over 3 inch lift using Drag Link Flip KIT

JK3056 - Use on JK Sport/Sahara (Dana 30 front axle) with under 3 inch lift using factory trackbar mounting location

JK4455 - Use on JK Rubicon (Dana 44 front axle) with over 3 inch lift using Drag Link Flip KIT

JK4456 - Use on JK Rubicon (Dana 44 front axle) with under 3 inch lift using factory trackbar mounting location

Notes:

- If your lift replaces your trackbar and mounts to the factory axle bracket (typical with a lift that includes an adjustable trackbar), choose Factory Height Bracket. If you are doing a Drag Link Flip (which requires a minimum 3 inch lift and bumpstop extensions), choose Raised Height Bracket.

- Some grinding and fitment may be required when installing this kit. Every axle varies slightly and some fabrication may be required.

- Stock axles have other components that may not hold up to the abuse of larger tires. Artec implies no guarantees that you will not break some component on your stock axles using larger tires. Use at you own risk.

- This kit is intended for vehicles with at least minor lifts (2.0 inch and up reccomended) and at least 1/2 inch bump stop extensions. Check clearances before installing. Not tested in non-US JKs or right hand drive axles.

- This kit requires general welding and fabrication skills including welding to the cast center section and cast inner c's. Welding should only be done by a competent welder. Artec Industries implies no guarantees or warranties and is not liable for improper installation.

- Some grinding and fitment may be required when installing this kit. Every axle varies slightly and some fabrication may be required.

- In rare and extreme cases, the truss may come into contact with oil pan. Prior to operating the vehicle, remove the coil springs, cycle the suspension including full compression of both sides simultaneously and add bumpstop extensions to prevent damage to oil pan.

Product Videos

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

JK APEX Front Axle Truss - A new era has begun with the arrival of the APEX Truss! Artec Industries is proud to announce the next generation of Patent Pending axle trusses. This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the APEX truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous versions with long weld seams can be lead to extra weld warping of the axle, longer install times and can be inconsistent.

This peaked structure not only applies to the axle tube between the coil perches but extends underneath the coil perches as well, forming a complete truss from end to end of axle, an industry first in an OEM axle application. The JK APEX Front Axle Truss has been secretly tested for over a year and a half proving that even though the truss is lighter weight, the peaked structure of the truss holds up to both extreme applications and daily driving.

The new JK APEX Front Axle Truss is the epitome of low cost, easy and quick to weld, simple, strong, and complete solutions for making your factory Jeep axle take more abuse than originally intended. You want easy insurance for your axle? The JK APEX Truss provides it.

JK Front LCA Skids - These heavy duty skids are designed to take serious abuse and reinforce your JL front axle lower control arm brackets. The 1/4 inch thick precision cut and formed components of this setup mean they'll install easily and protect your brackets and lower control arms.

JK Inner C Gussets - These heavy duty inner C gussets are designed to take serious abuse and reinforce your front Dana 30 or 44 JK Inner C's. The 1/4 inch thick precision cut and formed components precisely contour and wrap around your inner c and add rigidity.

JK APEX Trackbar Brackets - One of the weakest components of your factory axle is the axle side tracbar bracket and it's typically one of the main reasons for death wobble. Our new Heavy Duty Tracbar brackets are designed to work with our new APEX Truss and eliminate the issues caused by weak factory brackets.

They are seriously beefy and ready to take the abuse not to mention raise your steering stabilizer up and out of the way of rocks. For those running smaller lifts and are using an adjustable tracbar mounting to the the factory location, choose Stock Height. For those with taller lifts that require a Drag Link Flip, choose Raised Height.

How is this better than the Regular Armor Kit? This Kit includes entire replacement LCA brackets and Shock brackets whereas the regular Armor Kit just adds a skid plate to the factory LCA brackets.

Included in this kit:

- APEX Front Axle Truss

- Front LCA Skids

- Inner C Gussets

- APEX Heavy Duty Trackbar Bracket

Features include:

- Patent Pending APEX truss peaked top design provides more rigidity than a flat top truss design

- Truss is CNC Precision Laser cut in-house from 1/8 inch mild steel for a lightweight yet strong solution...only 7 lbs

- Truss is CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Dana Corp and Jeep for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- APEX design continues under the OEM coil buckets for complete end-to-end axle reinforcement...an industry first

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours to the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- Provides worry-free wheeling of up to 37 inch tires on stock JK axles

- Truss strengthens the weakest sections of the axle...under the coil perches, around the control arm brackets, and where the tube enters the casting

- Low Profile Design doesn't go over differential and allows usage in vehicles with only slight lift

- Front LCA Skids, Inner C Gussets and HD Trackbar Brackets made from 1/4 inch steel

- Skids, Gussets, and Brackets strengthen or replace weak components of the axle that are prone to failure

- Stock Trackbar

Note: Jeep offers different variations of axle housings. Please refer to the following diagram for details on which version to choose. If you have one model of a vehicle but have swapped in axles from another model, choose the model that the axles were originally in.

JK3055 - Use on JK Sport/Sahara (Dana 30 front axle) with over 3 inch lift using Drag Link Flip KIT

JK3056 - Use on JK Sport/Sahara (Dana 30 front axle) with under 3 inch lift using factory trackbar mounting location

JK4455 - Use on JK Rubicon (Dana 44 front axle) with over 3 inch lift using Drag Link Flip KIT

JK4456 - Use on JK Rubicon (Dana 44 front axle) with under 3 inch lift using factory trackbar mounting location

Notes:

- If your lift replaces your trackbar and mounts to the factory axle bracket (typical with a lift that includes an adjustable trackbar), choose Factory Height Bracket. If you are doing a Drag Link Flip (which requires a minimum 3 inch lift and bumpstop extensions), choose Raised Height Bracket.

- Some grinding and fitment may be required when installing this kit. Every axle varies slightly and some fabrication may be required.

- Stock axles have other components that may not hold up to the abuse of larger tires. Artec implies no guarantees that you will not break some component on your stock axles using larger tires. Use at you own risk.

- This kit is intended for vehicles with at least minor lifts (2.0 inch and up reccomended) and at least 1/2 inch bump stop extensions. Check clearances before installing. Not tested in non-US JKs or right hand drive axles.

- This kit requires general welding and fabrication skills including welding to the cast center section and cast inner c's. Welding should only be done by a competent welder. Artec Industries implies no guarantees or warranties and is not liable for improper installation.

- Some grinding and fitment may be required when installing this kit. Every axle varies slightly and some fabrication may be required.

- In rare and extreme cases, the truss may come into contact with oil pan. Prior to operating the vehicle, remove the coil springs, cycle the suspension including full compression of both sides simultaneously and add bumpstop extensions to prevent damage to oil pan.

Product Videos

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

JK Apex Front Axle Truss - A new era has begun with the Arrival of the Apex truss! Artec Industries is proud to announce the next generation of patent pending axle trusses. This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the Apex truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous versions with long weld seams can be lead to extra weld warping of the axle, longer install times and can be inconsistent. This peaked structure not only applies to the axle tube between the coil perches but extends underneath the coil perches as well, forming a complete truss from end to end of axle, an industry first in an OEM axle application.

The JK Apex Front Axle Truss has been secretly tested for over a year and a half proving that even though the truss is lighter weight, the peaked structure of the truss holds up to both extreme applications and daily driving. The new JK Apex Front Axle Truss is the epitome of low cost, easy and quick to weld, simple, strong, and complete solutions for making your factory Jeep axle take more abuse than originally intended. You want easy insurance for your axle? The JK Apex Truss provides it.

JK Front LCA Skids - These heavy duty skids are designed to take serious abuse and reinforce your JL front axle lower control arm brackets. The 1/4 inch thick precision cut and formed components of this setup mean they'll install easily and protect your brackets and lower control arms.

JK Inner C Gussets - These heavy duty inner C gussets are designed to take serious abuse and reinforce your front Dana 30 or 44 JK Inner C's. The 1/4 inch thick precision cut and formed components precisely contour and wrap around your inner c and add rigidity.

JK Apex Trackbar Brackets - One of the weakest components of your factory axle is the axle side Trackbar bracket and it's typically one of the main reasons for inchdeath wobble inch. Our new Heavy Duty Trackbar brackets are designed to work with our new Apex Truss and eliminate the issues caused by weak factory brackets. They are seriously beefy and ready to take the abuse not to mention raise your steering stabilizer up and out of the way of rocks. For those running smaller lifts and are using an adjustable Trackbar mounting to the the factory location, choose stock height. For those with taller lifts that require a drag link flip, choose raised height.

Features:

- Patent pending Apex truss peaked top design provides more rigidity than a flat top truss design

- Truss is CNC Precision Laser cut in-house from 1/8 inch mild steel for a lightweight yet strong solution...only 7 lbs

- Truss is CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Dana Corp and Jeep for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Apex design continues under the OEM coil buckets for complete end-to-end axle reinforcement...an industry first

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours to the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- Provides worry-free wheeling of up to 37 inch tires on stock JK axles

- Truss strengthens the weakest sections of the axle...under the coil perches, around the control arm brackets, and where the tube enters the casting

- Low Profile Design doesn't go over differential and allows usage in vehicles with only slight lift

- Front LCA Skids, Inner C Gussets and HD Trackbar Brackets made from 1/4 inch steel

- Skids, Gussets, and Brackets strengthen or replace weak components of the axle that are prone to failure

- With Raised Trackbar

- Differential: Dana 30

- Sold As: Kit

Product Videos

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

JK Apex Front Axle Truss - A new era has begun with the Arrival of the Apex truss! Artec Industries is proud to announce the next generation of patent pending axle trusses. This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the Apex truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous versions with long weld seams can be lead to extra weld warping of the axle, longer install times and can be inconsistent. This peaked structure not only applies to the axle tube between the coil perches but extends underneath the coil perches as well, forming a complete truss from end to end of axle, an industry first in an OEM axle application.

The JK Apex Front Axle Truss has been secretly tested for over a year and a half proving that even though the truss is lighter weight, the peaked structure of the truss holds up to both extreme applications and daily driving. The new JK Apex Front Axle Truss is the epitome of low cost, easy and quick to weld, simple, strong, and complete solutions for making your factory Jeep axle take more abuse than originally intended. You want easy insurance for your axle? The JK Apex Truss provides it.

JK Front LCA Skids - These heavy duty skids are designed to take serious abuse and reinforce your JL front axle lower control arm brackets. The 1/4 inch thick precision cut and formed components of this setup mean they'll install easily and protect your brackets and lower control arms.

JK Inner C Gussets - These heavy duty inner C gussets are designed to take serious abuse and reinforce your front Dana 30 or 44 JK Inner C's. The 1/4 inch thick precision cut and formed components precisely contour and wrap around your inner c and add rigidity.

JK Apex Trackbar Brackets - One of the weakest components of your factory axle is the axle side Trackbar bracket and it's typically one of the main reasons for inchdeath wobble inch. Our new Heavy Duty Trackbar brackets are designed to work with our new Apex Truss and eliminate the issues caused by weak factory brackets. They are seriously beefy and ready to take the abuse not to mention raise your steering stabilizer up and out of the way of rocks. For those running smaller lifts and are using an adjustable Trackbar mounting to the the factory location, choose stock height. For those with taller lifts that require a drag link flip, choose raised height.

Features:

- Patent pending Apex truss peaked top design provides more rigidity than a flat top truss design

- Truss is CNC Precision Laser cut in-house from 1/8 inch mild steel for a lightweight yet strong solution...only 7 lbs

- Truss is CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Dana Corp and Jeep for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Apex design continues under the OEM coil buckets for complete end-to-end axle reinforcement...an industry first

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours to the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- Provides worry-free wheeling of up to 37 inch tires on stock JK axles

- Truss strengthens the weakest sections of the axle...under the coil perches, around the control arm brackets, and where the tube enters the casting

- Low Profile Design doesn't go over differential and allows usage in vehicles with only slight lift

- Front LCA Skids, Inner C Gussets and HD Trackbar Brackets made from 1/4 inch steel

- Skids, Gussets, and Brackets strengthen or replace weak components of the axle that are prone to failure

- With Stock Trackbar

- Differential: Dana 30

- Sold As: Kit

Product Videos

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

JK Apex Front Axle Truss - A new era has begun with the arrival of the Apex truss! Artec Industries is proud to announce the next generation of patent pending axle trusses. This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the Apex truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous versions with long weld seams can be lead to extra weld warping of the axle, longer install times and can be inconsistent. This peaked structure not only applies to the axle tube between the coil perches but extends underneath the coil perches as well, forming a complete truss from end to end of axle, an industry first in an OEM axle application.

The JK Apex Front Axle Truss has been secretly tested for over a year and a half proving that even though the truss is lighter weight, the peaked structure of the truss holds up to both extreme applications and daily driving. The new JK Apex Front Axle Truss is the epitome of low cost, easy and quick to weld, simple, strong, and complete solutions for making your factory Jeep axle take more abuse than originally intended. You want easy insurance for your axle? The JK Apex Truss provides it.

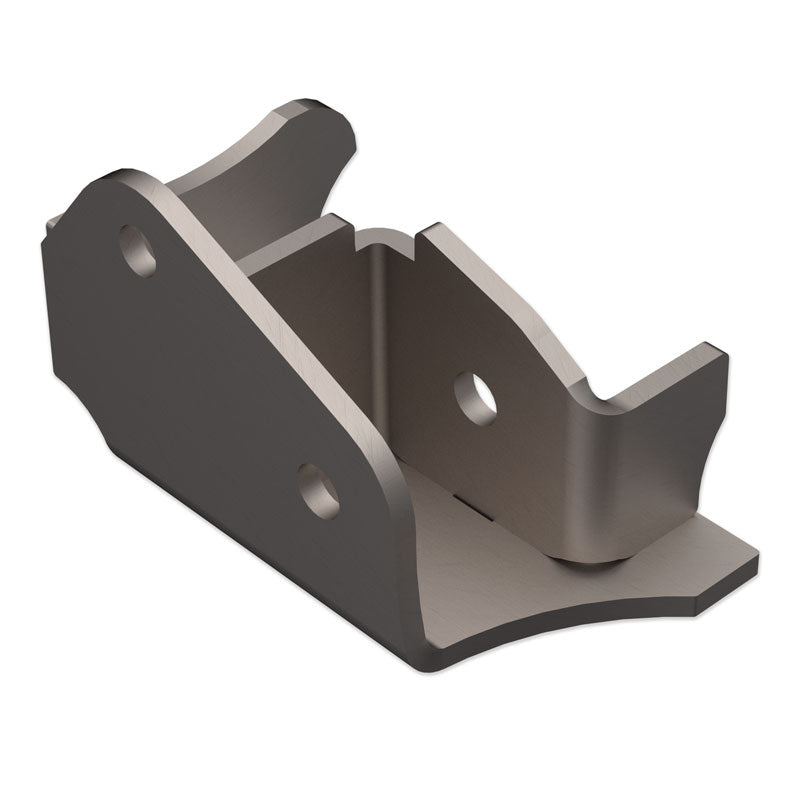

JK Front LCA Brackets - While Skids work well, sometimes a whole bracket replacement is needed. These Heavy Duty brackets go a step further than the factory brackets by integrating a skid plate underneath and wrapping more fully around the axle tube. Those factory tin foil brackets of your are probably bent anyways, so these steel 1/4 inch thick replacements will ensure that you have the toughest front axle.

JK Shock Brackets - Take hit a little too hard and boom, your factory shock bracket bends or breaks right off the axle. Not going to happen with these steel 1/4 inch thick replacement shock brackets. No more worrying.

JK Inner C Gussets - These heavy duty inner C gussets are designed to take serious abuse and reinforce your front Dana 30 or 44 JK Inner C's. The 1/4 inch thick precision cut and formed components precisely contour and wrap around your inner c and add rigidity.

JK Apex Trackbar Brackets - One of the weakest components of your factory axle is the axle side Trackbar bracket and it's typically one of the main reasons for death wobble. Our new Heavy Duty Trackbar brackets are designed to work with our new Apex Truss and eliminate the issues caused by weak factory brackets. They are seriously beefy and ready to take the abuse not to mention raise your steering stabilizer up and out of the way of rocks. For those running smaller lifts and are using an adjustable Trackbar mounting to the the factory location, choose stock height. For those with taller lifts that require a drag link flip, choose raised height.

How is this better than the regular Armor Kit? This Kit includes entire replacement LCA brackets and Shock brackets whereas the regular Armor Kit just adds a skid plate to the factory LCA brackets.

Features:

- Patent Pending Apex truss peaked top design provides more rigidity than a flat top truss design

- Truss is CNC Precision Laser cut in-house from 1/8 inch mild steel for a lightweight yet strong solution...only 7 lbs

- Truss is CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Dana Corp and Jeep for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- APEX design continues under the OEM coil buckets for complete end-to-end axle reinforcement...an industry first

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours to the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- Provides worry-free wheeling of up to 37 inch tires on stock JK axles

- Truss strengthens the weakest sections of the axle...under the coil perches, around the control arm brackets, and where the tube enters the casting

- Low Profile Design doesn't go over differential and allows usage in vehicles with only slight lift

- Front LCA Brackets, Shock Brackets, Inner C Gussets and HD Trackbar Brackets made from 1/4 inch steel

- Gussets, and Brackets strengthen or replace weak components of the axle that are prone to failure

- With Raised Trackbar

- Differential: Dana 30

- Sold As: Kit

Product Videos

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

JK Apex Front Axle Truss - A new era has begun with the arrival of the Apex truss! Artec Industries is proud to announce the next generation of patent pending axle trusses. This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the Apex truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous versions with long weld seams can be lead to extra weld warping of the axle, longer install times and can be inconsistent. This peaked structure not only applies to the axle tube between the coil perches but extends underneath the coil perches as well, forming a complete truss from end to end of axle, an industry first in an OEM axle application.

The JK Apex Front Axle Truss has been secretly tested for over a year and a half proving that even though the truss is lighter weight, the peaked structure of the truss holds up to both extreme applications and daily driving. The new JK Apex Front Axle Truss is the epitome of low cost, easy and quick to weld, simple, strong, and complete solutions for making your factory Jeep axle take more abuse than originally intended. You want easy insurance for your axle? The JK Apex Truss provides it.

JK Front LCA Brackets - While Skids work well, sometimes a whole bracket replacement is needed. These Heavy Duty brackets go a step further than the factory brackets by integrating a skid plate underneath and wrapping more fully around the axle tube. Those factory tin foil brackets of your are probably bent anyways, so these steel 1/4 inch thick replacements will ensure that you have the toughest front axle.

JK Shock Brackets - Take hit a little too hard and boom, your factory shock bracket bends or breaks right off the axle. Not going to happen with these steel 1/4 inch thick replacement shock brackets. No more worrying.

JK Inner C Gussets - These heavy duty inner C gussets are designed to take serious abuse and reinforce your front Dana 30 or 44 JK Inner C's. The 1/4 inch thick precision cut and formed components precisely contour and wrap around your inner c and add rigidity.

JK Apex Trackbar Brackets - One of the weakest components of your factory axle is the axle side Trackbar bracket and it's typically one of the main reasons for death wobble. Our new Heavy Duty Trackbar brackets are designed to work with our new Apex Truss and eliminate the issues caused by weak factory brackets. They are seriously beefy and ready to take the abuse not to mention raise your steering stabilizer up and out of the way of rocks. For those running smaller lifts and are using an adjustable Trackbar mounting to the the factory location, choose stock height. For those with taller lifts that require a drag link flip, choose raised height.

How is this better than the regular Armor Kit? This Kit includes entire replacement LCA brackets and Shock brackets whereas the regular Armor Kit just adds a skid plate to the factory LCA brackets.

Features:

- Patent Pending Apex truss peaked top design provides more rigidity than a flat top truss design

- Truss is CNC Precision Laser cut in-house from 1/8 inch mild steel for a lightweight yet strong solution...only 7 lbs

- Truss is CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Dana Corp and Jeep for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- APEX design continues under the OEM coil buckets for complete end-to-end axle reinforcement...an industry first

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours to the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- Provides worry-free wheeling of up to 37 inch tires on stock JK axles

- Truss strengthens the weakest sections of the axle...under the coil perches, around the control arm brackets, and where the tube enters the casting

- Low Profile Design doesn't go over differential and allows usage in vehicles with only slight lift

- Front LCA Brackets, Shock Brackets, Inner C Gussets and HD Trackbar Brackets made from 1/4 inch steel

- Gussets, and Brackets strengthen or replace weak components of the axle that are prone to failure

- With Stock Trackbar

- Differential: Dana 30

- Sold As: Kit

Product Videos

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

A new era has begun with the arrival of the Apex truss! Artec Industries is proud to announce the next generation of patent pending axle trusses.

This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the Apex truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous versions with long weld seams can lead to extra weld warping of the axle, longer install times and can be inconsistent.

This peaked structure not only applies to the axle tube between the coil perches but extends underneath the coil perches as well, forming a complete truss from end to end of axle, an industry first in an OEM axle application. The JK Apex Truss that was secretly tested for over a year and a half proving that even though the truss is lighter weight, the peaked structure of the truss holds up to both extreme applications and daily driving.

The new JK Apex Front Axle Truss is the epitome of low cost, easy and quick to weld, simple, strong, and complete solutions for making your factory Jeep axle take more abuse than originally intended. You want easy insurance for your axle? The JK Apex Truss provides it.

Features:

- Patent Pending Apex truss peaked top design provides more rigidity than a flat top truss design

- Truss is CNC Precision Laser cut in-house from 1/8 inch mild steel for a lightweight yet strong solution...only 7 lbs

- Truss is CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Dana Corp and Jeep for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Apex design continues under the OEM coil buckets for complete end-to-end axle reinforcement...an industry first

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours to the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- Provides worry-free wheeling of up to 37 inch tires on stock JK axles

- Truss strengthens the weakest sections of the axle...under the coil perches, around the control arm brackets, and where the tube enters the casting

- Low Profile Design doesn't go over differential and allows usage in vehicles with only slight lift

- Differential: Dana 30

- Sold As: Each

Notes:

- Some grinding and fitment may be required when installing this kit. Every axle varies slightly and some fabrication may be required.

- Stock axles have other components that may not hold up to the abuse of larger tires. Artec implies no guarantees that you will not break some component on your stock axles using larger tires. Use at you own risk.

- In rare and extreme cases, the truss may come into contact with oil pan. Prior to operating the vehicle, remove the coil springs, cycle the suspension including full compression of both sides simultaneously and add bumpstop extensions to prevent damage to oil pan.

- This kit is intended for vehicles with at least minor lifts (2.0 Inch and up recommended) and at least 1/2 inch bump stop extensions. Check clearances before installing. Not tested in non-US JKs or right hand drive axles.

Product Videos

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

A new era has begun with the arrival of the Apex truss! Artec Industries is proud to announce the next generation of patent pending axle trusses.

This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the Apex truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous versions with long weld seams can lead to extra weld warping of the axle, longer install times and can be inconsistent.

This peaked structure not only applies to the axle tube between the coil perches but extends underneath the coil perches as well, forming a complete truss from end to end of axle, an industry first in an OEM axle application. The JK Apex Truss that was secretly tested for over a year and a half proving that even though the truss is lighter weight, the peaked structure of the truss holds up to both extreme applications and daily driving.

The new JK Apex Front Axle Truss is the epitome of low cost, easy and quick to weld, simple, strong, and complete solutions for making your factory Jeep axle take more abuse than originally intended. You want easy insurance for your axle? The JK Apex Truss provides it.

Features:

- Patent Pending Apex truss peaked top design provides more rigidity than a flat top truss design

- Truss is CNC Precision Laser cut in-house from 1/8 inch mild steel for a lightweight yet strong solution...only 7 lbs

- Truss is CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Dana Corp and Jeep for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Apex design continues under the OEM coil buckets for complete end-to-end axle reinforcement...an industry first

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours to the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- Provides worry-free wheeling of up to 37 inch tires on stock JK axles

- Truss strengthens the weakest sections of the axle...under the coil perches, around the control arm brackets, and where the tube enters the casting

- Low Profile Design doesn't go over differential and allows usage in vehicles with only slight lift

- Differential: Dana 44

- Sold As: Each

Notes:

- Some grinding and fitment may be required when installing this kit. Every axle varies slightly and some fabrication may be required.

- Stock axles have other components that may not hold up to the abuse of larger tires. Artec implies no guarantees that you will not break some component on your stock axles using larger tires. Use at you own risk.

- In rare and extreme cases, the truss may come into contact with oil pan. Prior to operating the vehicle, remove the coil springs, cycle the suspension including full compression of both sides simultaneously and add bumpstop extensions to prevent damage to oil pan.

- This kit is intended for vehicles with at least minor lifts (2.0 Inch and up recommended) and at least 1/2 inch bump stop extensions. Check clearances before installing. Not tested in non-US JKs or right hand drive axles.

Product Videos

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

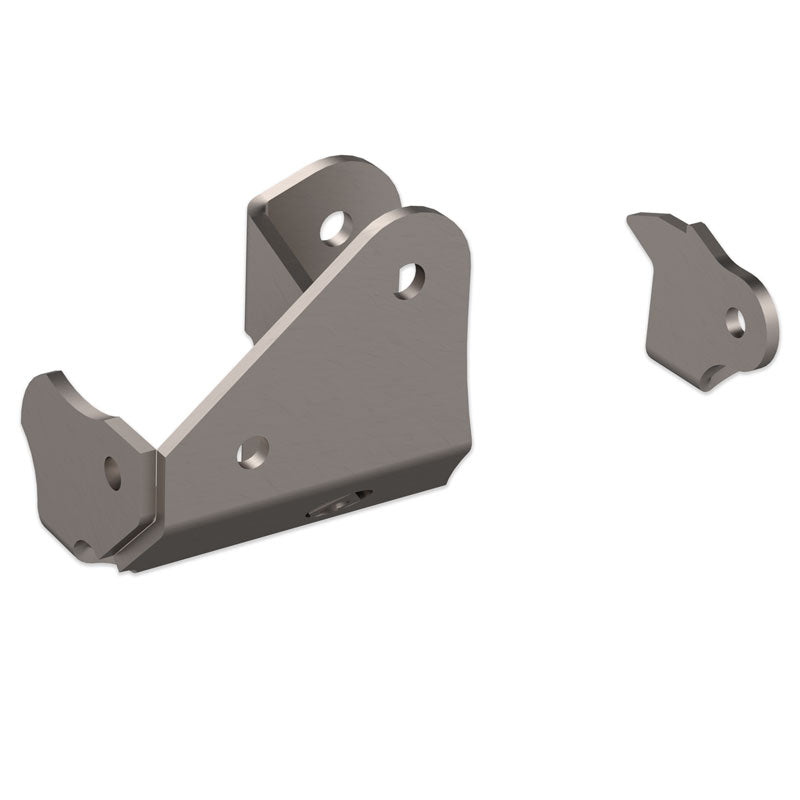

This heavy bracket is designed to take serious abuse and replace your front 30 or 44 JK factory trackbar bracket. The 1/4 inch thick precision cut and formed components of this setup out perform the competition.

Features:

- Integrates with new Apex truss for JK (late 2019). Not for use with 1st Generation Artec Trusses (prior to Nov 2019)

- 1/4 inch mild steel

- Precision CNC cut and bent for great fitment

- Replaces factory bracket for those with 2.0 inch lift or higher

- Lifts factory sway bar mount 1.75 inch

- Adjusts roll center 3 inches higher for greater stability

- Allows rotation of steering dampener to top side of tie rod for greater clearance

- Improves ground clearance over factory brackets

- Sold As: Each

Note: This bracket offers raised trackbar holes at 3.0 inch. This bracket is for use with a drag link flip (which requires a new trackbar, minimum 3.0 inch lift and bumpstop extensions). This bracket has nothing to do with your lift amount.

Note: If your lift replaces your trackbar and mounts to the factory axle bracket (typical with a lift that includes an adjustable trackbar), choose stock height bracket.

Product Videos

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

This heavy bracket is designed to take serious abuse and replace your front 30 or 44 JK factory trackbar bracket. The 1/4 inch thick precision cut and formed components of this setup out perform the competition.

Features:

- Integrates with new Apex Truss for JK (late 2019)

- Not for use with 1st Generation Artec Trusses (prior to Nov 2019)

- 1/4 inch mild steel

- Precision CNC cut and bent for great fitment

- Replaces factory bracket to prevent death wobble or other issues

- Lifts factory sway bar mount 1.75 inch

- Allows rotation of steering dampener to top side of tie rod for greater clearance

- Improves ground clearance over factory brackets.

- Sold As: Each

Note: If your lift replaces your trackbar and mounts to the factory axle bracket (typical with an lift that includes an adjustable trackbar), choose this bracket.

Product Videos

Vehicle Fitments

- Jeep Wrangler 2007 to 2017

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

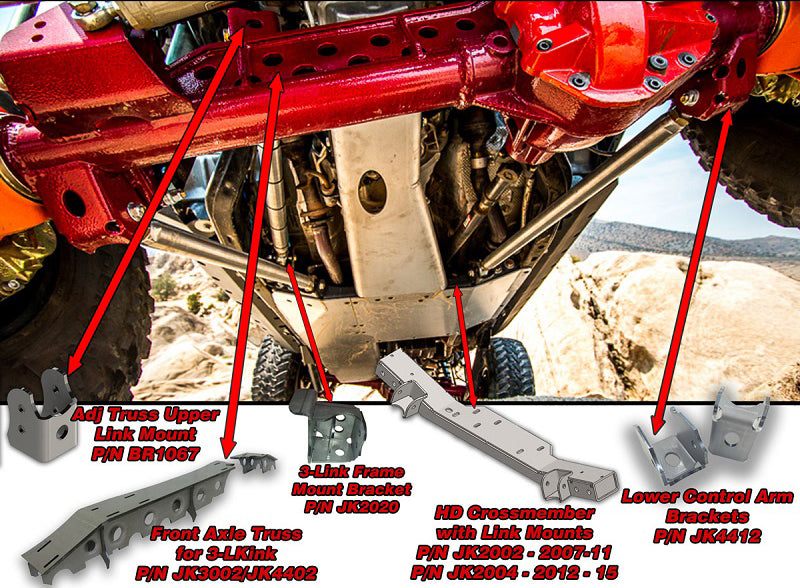

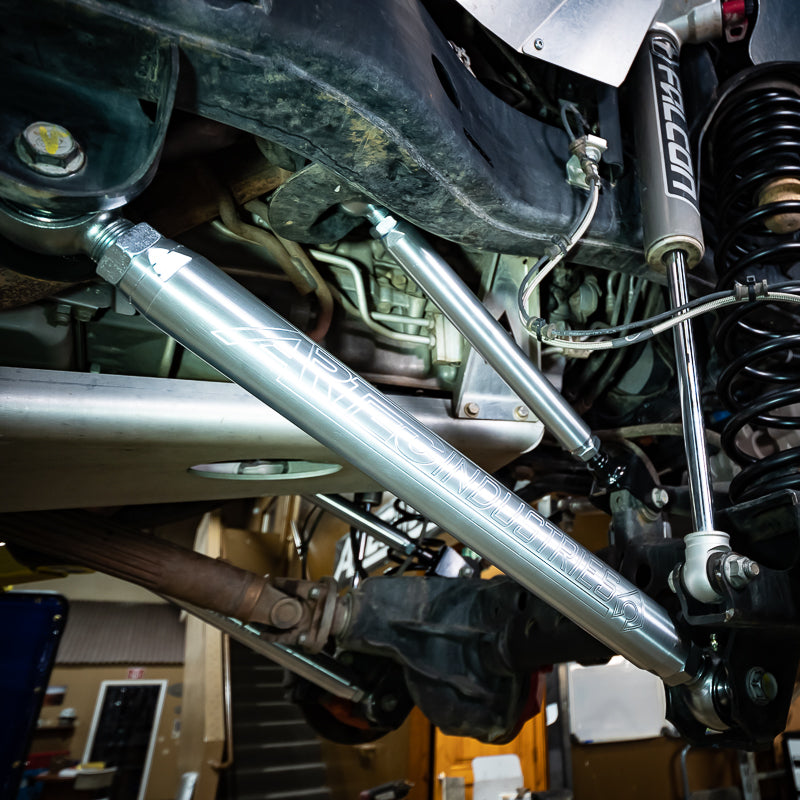

We started the Jeep 1 ton Revolution and now we're taking it to the next level. The new APEX swap kit is designed to have a simpler, faster install, with less parts and weight and lower price.

We've worked hard to improve everything, from making the truss easier to weld, to less warping from welding, to optimizing the shock bracket locations and lowering the upper control arm mounts for more clearance and better geometry.

The improvements made have been suggested by our network of dealer/installers who build these kits every day. Now they are a reality. The New 1 Ton APEX Front Swap Kit delivers in every way.

This heavy duty truss and bracket system is designed to take serious abuse and reinforce your entire axle while also providing the factory link, spring, anti-sway bar, and shock locations.

The 3/16 inch thick truss incorporates a unique peaked design to strengthen both the axle and incorporate the link brackets for ease of installation and added strength.

By using the truss to align the link mounts, hours of work and trial and error can be avoided when compared to other bracket systems.

Simply tack weld the truss on the axle, and all the other brackets fit into place exactly where they need to be.

Features include:

- Patent Pending APEX Truss peaked top design provides more rigidity than a flat top truss design

- Significantly lighter weight than comparable junkyard axle housings

- Co-developed with Professional Ultra 4 racer Erik Miller of Miller Motorsports

- CNC Precision Laser cut in-house from 1/4 inch and 3/16 inch mild steel for a lightweight yet strong solution...starting at only 32 lbs total

- CNC Precision Bent in-house for a great fitment. Literally drop the truss in place on the axle and it's ready to weld. No puzzle piece assembling

- Designed used 3D models directly from Spidertrax and Jeep for not only an amazing fit but clearances with surrounding components

- 70 percent less welding needed than previous truss designs means less warping, faster turnaround, and lower costs

- All long seams are bent so you don't need to spend time welding them together

- Dimpled holes provide not only weight reduction but rigidity and strength

- Contours the Spidertrax differential for a precise fit and ultimate rigidity

- OEM location Upper Control Arms mount to truss (bushing or Johnny Joint option)

- UCA brackets install Tool included for easy and precise assembly

- Truss extends under coil buckets all the way to inner C for end-to-end rigidity

- Multi-piece truss design means smaller packaging and less shipping costs along with easy installation

- Using a 1 ton axle will support larger tires and less chance of breakage in extreme conditions

- Coil brackets and bump stop pads are combined to form an axle tube truss and allows for easy installment of other brackets

- Includes all the brackets necessary for a complete axle swap including upper and lower control arm mounts, shock mounts, anti-sway bar mounts, trackbar mount, bumpstop pads and coil spring mounts.

- Heavy duty Trackbar bracket can slide to multiple positions for steering geometry fine tuning

- Shock brackets have been moved out (compared JK OEM position) for a higher clearance when using larger shocks

- Lower Control Arm brackets located in the OEM position for a true bolt-in application

- Overall low profile design means your axle is stronger, sleeker, easier to fit into any vehicle, and less likely to interfere with vehicle components.

- UCA Mount Style: Daystar Bushings

- Sold As: Kit

Important Notes:

- The Spidertrax 9 inch axle comes with equal length axle tube and will require cutting the tubes to make the correct offset for a front axle. Different WMS widths are possible with this kit so measurements are not provided. Measuring and cutting the axle is the responsibility of the end user and Artec Industries is not responsible

- for incorrect cutting. Please mock up swap kit components and inner c's prior to making any cuts.

- Axle housing and inner c's not included in this swap kit.

- This kit does not include any parts for ABS sensors. It is only a bracket kit. Hooking up and configuring these sensors is the responsibility of the end user.

- 1 ton axles do not match the factory JK 5 lug wheel bolt pattern. New wheels will need to be purchased to do this swap. Brake and Steering components not included in this product, but will be available soon.

- This will likely require bumpstop extensions and a new trackbar since the steering is different on this axle from factory axle. The trackbar bracket is higher than stock location to allow proper steering geometry.

Product Videos

Vehicle Fitments

- Jeep Wrangler 2007 to 2020

- Jeep Gladiator 2020 to 2021

- Jeep Wrangler JK 2018 to 2018

Additional Attributes

- 2 years warranty

- Delivery time: 1-2 business days

- Free 90 days return

We started the Jeep 1 ton Revolution and now we're taking it to the next level. The new APEX swap kit is designed to have a simpler, faster install, with less parts and weight and lower price.

We've worked hard to improve everything, from making the truss easier to weld, to less warping from welding, to optimizing the shock bracket locations and lowering the upper control arm mounts for more clearance and better geometry.

The improvements made have been suggested by our network of dealer/installers who build these kits every day. Now they are a reality. The New 1 Ton APEX Front Swap Kit delivers in every way.

This heavy duty truss and bracket system is designed to take serious abuse and reinforce your entire axle while also providing the factory link, spring, anti-sway bar, and shock locations.

The 3/16 inch thick truss incorporates a unique peaked design to strengthen both the axle and incorporate the link brackets for ease of installation and added strength.